Table of Contents

When crafting any plumbing system, you’re going to utilize at least a few PVC connectors. Knowing how to properly adjoin pipe sections with coupling is the key to your success. When you rely on the quality PVC products that Lesso produces, you’ll be well on your way to creating a long-lasting plumbing system.

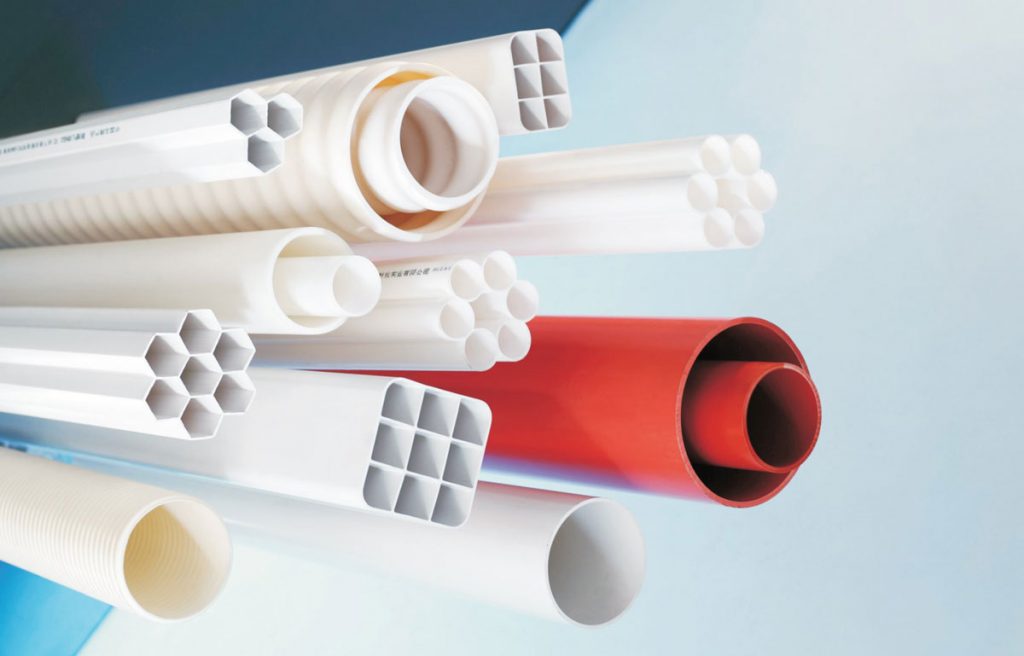

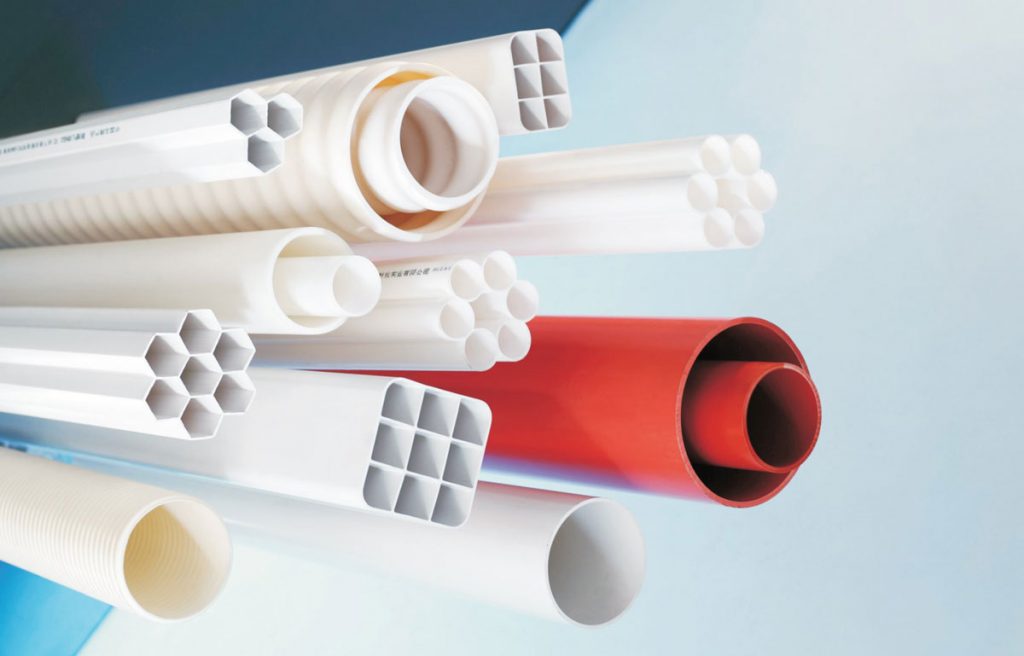

In today’s plumbing industry, there’s only one standard material utilized in all drain systems. This material is PVC, known as polyvinyl chloride and it’s available at LESSO in many different fittings and pipe sizes for an affordable price.

You’ll find this material in residential, commercial, and industrial plumbing systems thanks to its ease of installation, durability, and affordability for property owners. A necessary component of assembling PVC piping is coupling.

What is a PVC Coupling?

At its most basic definition, a coupling is utilized to join two pieces of material together to form one solid piece. When it comes to PVC, you’ll need to use PVC couplings to join together different sections of PVC piping to formulate an interconnected residential or commercial plumbing system. Each coupling will have groove indentations that will allow specific size piping to fit into either side of the connector.

PVC connectors are readily available in a number of different sizes, including one-and-a-half, two, three, four, and five inches. The connector’s particular size indicates the size of piping that it can join. For example, a two-inch PVC connector will join two sections of two-inch PVC piping.

Required Tools and Materials to Connect PVC Pipe and Couplings

Working with PVC is straightforward for both homeowners and plumbing professionals. The process doesn’t require many specialized tools, adding to its appeal and versatility. PVC pipe joints are typically bonded using adhesive.

If you’re adjusting existing piping, tools like a pipe cutter, measuring tape, and a marker are essential to ensure you achieve the correct size for your coupling. Always refer to the specific product guidelines when working with PVC to ensure compatibility and proper installation.

When assembling PVC joints using our products, it’s essential to follow specific steps for optimal results. First, use tools like a fine-toothed saw, cutter, or dedicated PVC-U pipe cutter to cut the pipe evenly and vertically.

After cutting, remove any burrs or rough edges and bevel the end of the pipe. Before applying the adhesive, ensure the bonding surfaces are clean, free of dust, debris, and any oil or water residue. Using a brush, evenly and quickly apply the specialized adhesive to the bonding surfaces of both the pipe and fitting.

To ensure uniform distribution of the adhesive, swiftly insert the pipe into the fitting, turning it a quarter circle. Wipe away any excess adhesive from the pipe’s surface. It’s crucial to wait for 24 hours after assembly before conducting any water pressure tests. Remember, this method is specific to our products, so always refer to our guidelines for the best results.

Step-By-Step Guide to Connect PVC Pipe Couplings

Connecting PVC piping to PVC pipe couplings is a fairly straightforward process. You want to start by measuring your existing PVC piping and ensure that you’re getting the right length where it will fit inside the coupling snugly up to the groove. If you’re not using a traditional pipe cutter, you’ll want to ensure that you debur any debris that’s left on the edge of the piping when you cut it.

Next, you want to dry-fit the piping into the coupler to ensure that it will fit correctly before you add any sort of primer or cement. When everything looks like it’s going to fit snugly, it’s time to put on some gloves and apply a coat of PVC primer.

You want to apply this to the outside of the pipe as well as the inside of the coupling. You want to give the primer about a minute to dry before you apply the PVC cement.

Make sure that when applying the cement, you do so over the areas that you have already primed on both the pipe and the inside of the coupling. Next, you’ll want to insert the piping into the coupling and turn it a quarter of a turn to ensure that all the molecules from the piping bond perfectly with the molecules from the coupling.

The cement should dry within about 30 seconds while you hold the connection in place. You want to give the newly created joint at least 30 minutes before applying excessive pressure or testing water throughout. This will allow the joint to properly cure.

Tips for a Successful PVC Coupling Connection

While using a PVC coupling is fairly straightforward, it’s important to pay attention to a few key tips that will ensure that every joint you make is long-lasting. First and foremost, you always want to ensure that you have your pipes dry-fitted snugly and that there are no rough edges that need to be deburred before using the cement.

While there’s a lot of talk online about people utilizing PVC cement without a primer first, it’s not recommended. Your joints won’t be as strong or as long-lasting if you don’t properly use a primer to get rid of surface debris on the pipe and coupling.

Common PVC Coupling Connection Issues and Solutions

When people are first starting to learn how to connect PVC pipe to existing piping through PVC connectors, it can be a little overwhelming. There are a ton of PVC pipe fittings names that can be a bit confusing.

One of the biggest problems that many people experience when trying to create their first coupler connection is not adequately applying a liberal amount of both primer and cement to their joints. Priming is an absolute necessity to ensure that the piping and the coupler are ready to be fused together. The cement ensures that the fusion process can take place.

Leaks in PVC Connectors

There are a couple of different reasons that you may develop a leak in your PVC connectors. This could be due to an inadequate connection because of a misaligned angle of the piping coming into the connector.

It could be due to the fact that the piping inserted into the connector did not get adequately inserted the whole way up to the groove. This can also be due to a lack of adequate PVC cement being applied to the piping as well as the inside of the coupling.

Misaligned PV Coupling Connections

One of the most common PVC coupling connection problems that homeowners experience is connecting a pipe at an unsafe angle to the coupling. Couplings are specifically designed to have PVC pipes enter them at a direct angle.

If your PVC piping is coming in at any angle other than directly straight on, it can cause unnecessary air gaps between the piping and the inside of the coupling. Whenever you go to install your primer and cement, the piping and coupling materials won’t properly adhere to one another. This will almost always result in a leaky joint or one that completely falls apart.

Marinating Your PVC Connectors

Maintaining your new PVC connectors is fairly effortless. Ensure that you’re not putting anything down the piping that could be detrimental to its overall well-being, such as chemicals. Additionally, you want to ensure that you’re not putting any pressure up against the piping or the coupler that could eventually cause the joint to fail.

PVC Connectors Maintenance and Troubleshooting Tips

If you’re experiencing a failure in one of your PVC couplings, it’s an indication that it wasn’t constructed appropriately, to begin with. Unfortunately, there is no quick fix to a failed coupling.

You’ll need to use a pipe cutter or a similar tool to completely remove the coupling altogether. You never want to try and reuse a coupling that you already put PVC cement on, as it could interfere with a successful bond for a new joint in the future.

When constructing a plumbing system, it’s only going to be as strong as the joints created at the couplers. Using quality PVC products will ensure that you have a long-lasting connection so that you can rely heavily on your new plumbing system for decades to come.

What’s the Difference Between PVC Pipe and PVC Conduit

Table of Contents PVC or Polyvinyl Chloride pipes use vinyl and plastic materials. We use these pipes in plumbing systems. If you do not want

How to Cut and Assemble PVC Pipes Easily?

Table of Contents We primarily use PVC pipes for our water transportation system because they are safe for consumption and other domestic purposes. Remember how metal