Table of Contents

HDPE plastic or high-density polyethylene is a thermoplastic resin, and it’s used for many different types of residential, commercial, and industrial applications. While HDPE may sound like a new product, it’s actually been around for close to a century.

The development of HDPE started in 1925 at the Phillips Petroleum Company. Geroge Oberfell, the research director, wanted to find additional uses for natural gas and pitched the idea to Frank Phillips. The pitch was a winner, and by 1927, the first hydrocarbon research laboratory was established. By WWII, HDPE had been created, and the product was used to make high-frequency radar cables. This type of HDPE is known as low-density because it’s flexible.

At the end of the war, the research lab wanted to do something with propylene and ethylene, which, at the time, were waste products from the natural gas refining process. They decided to use nickel oxide with small amounts of chromium oxide.

During the experiment, they fed the propane and propylene through a pipe filled with nickel oxide and chromium oxide. As the substance flowed out of the tube, they noticed white solids. It was crystalline polypropylene, which is a general-purpose resin that’s used to make HDPE.

Today, HDPE plastic is used to make plumbing pipes, plastic bottles, plastic containers, and toys. In fact, you probably have some HPDE in your home, like a compost bin, plastic lumber, or outdoor furniture.

Properties and Advantages of HDPE

HDPE is versatile, durable, and corrosion and damage-resistant. Its chemical formula is C2H4, and it has a density of 961 kg/m3 and a tensile strength that’s greater than 3,500 psi. Its melting point is 269.24 F.

It's extremely malleable

HDPE is preferred in many different types of applications due to its rigidness and resistance to environmental factors. However, once it reaches its melting point of 269 F, it becomes extremely malleable, and it’s this malleability that allows it to be formed into a variety of shapes, including pipes, containers, and toys.

It can be recycled

While many plastics get a bad rap for being difficult to recycle, items manufactured from HDPE don’t have that problem. In fact, about 31 percent of HDPE plastics get recycled. This is because HDPE is recycled by removing any debris or non-plastic pieces then it is separated by density. Finally, it’s shredded, melted, and formed into plastic pellets that are then transported back to the manufacturers.

It is extremely weather-resistant

HDPE doesn’t break down or degrade due to environmental factors or the weather. it’s resistant to acid, solvents, chemicals soaps, and detergents. This makes it an ideal product for the creation of industrial pipes, plastic bottles, food packaging, and chemical storage containers, like drain cleaners. It can also be used to make outdoor furniture, trash cans, and playground equipment.

HDPE is cost-effective

HDPE is often more cost-effective than other types of materials. This is because it’s relatively inexpensive to produce. It’s also lightweight, which means it costs less to ship and transport. Because of its lightweight, less fuel is required when transporting HDPE, and there’s less wear and tear on the roadways.

What Is HDPE Used for?

There are many HDPE uses. High-density polyethylene is often used for potable water pipes, sewer and drain lines, gas mains, electrical conduits, and plastic lumber and decking. In fact, you can find HDPE products in the plumbing, electrical, and manufacturing industries.

Potable Water Pipes

HDPE pipes are safe for potable water. This is because they are highly resistant to corrosion and tend to stay leak-free due to their tight fittings. HDPE pipes are cost-effective and lightweight, and they don’t contribute to chemical leaching. HDPE pipes can withstand temperatures from -148 to 176 F, which means they’ll even work well for residential hot water applications.

Sewer and Drain Lines

HDPE pipes do not break down due to the chemicals and components in the soil, and they are UV resistant. This makes them an ideal material for sewage and drain pipes as well as stormwater systems.

Gas Mains

Gas mains are held to extremely high standards due to the volatility of gas and the dangers of leaks. Thankfully, HDPE is an ideal solution due to its tight fittings, superior strength, flexibility, and low material cost.

Industrial Piping

HDPE plastic is resistant to corrosion and chemicals. It’s difficult to crack and abrasion-resistant. This makes it ideal for industrial, pharmaceutical, and food manufacturing applications.

Electrical Conduits

HDPE pipes do not conduct electricity, and they are resistant to moisture and environmental factors. This makes them ideal for protecting electrical wires and cables that are located underground or inside walls.

Lumber and Decking

HDPE is often used to make plastic lumber, and lumber can be used to build decking, bridges, and even marine docks. This material is often preferred over wood because it doesn’t rot or attract pests.

Trash Cans and Compost Bins

HDPE is often used to manufacture trash cans and compost bins due to its extreme durability and resistance to cracking. This means that trash trucks can pick up these cans with mechanical arms and not damage them. HDPE trash cans and compost bins are also resistant to mold and mildew growth and pests, and once they reach the end of their useful lives, they can be recycled into other products. In fact, it’s estimated that HDPE can be recycled up to ten times.

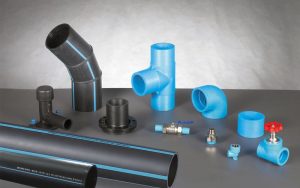

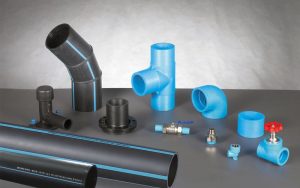

HDPE Plastic Pipes and Fittings from LESSO

If you are in need of high-quality HDPE plastic pipes and fittings, Lesso has you covered. Our HDPE products are renowned for their exceptional durability and chemical resistance, making them ideal for a wide range of industrial and construction applications.

Committed to sustainable solutions, we ensure that every product meets the highest standards of quality. By choosing Lesso for your HDPE pipe and fitting needs, you are opting for unmatched quality and reliability. Contact us to learn more and experience our professional service and support.

FAQs about HDPE

HDPE has good heat resistance but may deform under extreme temperatures.

HDPE is generally considered safe and doesn’t leach chemicals under normal conditions.

Yes, its strength and chemical resistance make it ideal for underground pipes.

Recommend Reading

Discover the Power of HDPE Pipes for Industrial Use

Table of Contents If you are looking for material that is strong, flexible and can be used in a variety of different environments, you should

The Comparison of PE Pipe and HDPE Pipe

Plastic products have been in use for many decades. With advancements in technology, more thermoplastic products have graced the industries and more is expected to