Utility infrastructures rely on the quality of piping for efficiency and effective delivery. High-density polyethylene (HDPE) pipes are most common in these projects as they can withstand high temperatures and pressure, besides being weather resistant. However, the available brands vary in quality depending on the HDPE pipe manufacturers. Here is all you need to know about HDPE pipes.

What is the HDPE pipe?

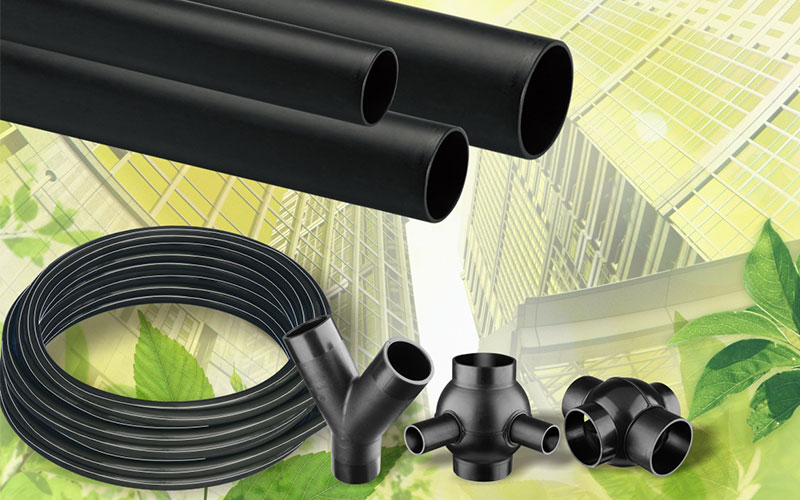

HDPE Pipes are ergonomic plastic pipes that transfer items in various sectors, like water, electrical, irrigation, sewer, and air mains. They are ideal for delivering compressed gases and liquids like wastewater/chemicals, slurries, etc.

HDPE pipes are made from a flexible thermoplastic, so they are perfect for replacing damaged steel or concrete pipelines. These pipes are not only impermeable but also have unmatched tensile strength for durability. Furthermore, HDPE pipes are cost-effective, corrosion-resistant, and lightweight.

Unlike in the previous decades, more companies are today opting for HDPE pipe fittings for their affordability and efficiency. Users recognize the environmentally friendly nature of HDPE pipes, hence, their application as a green solution. You can rely on HDPE pipes to significantly minimize your carbon footprint.

Is HDPE the same as PE?

Polyethylene (PE) pipe is the general term referring to thermoplastic pipes made from ethylene gas. PE pipes come in different types that range from very-low-density, low-density, cross-linked, ultra-low-molecular-weight, high-molecular-weight, medium-density, ultrahigh molecular weight, chlorinated, and linear low-density.

HDPE meaning refers to a type of PE pipes that are denser than the basic pipe types. HDPE pipes are less flexible than ordinary samples because they come with high melting and impact points. During manufacturing, companies may add carbon black or other colors to HDPE pipes for UV resistance.

You can get HDPE pipes with triple, double, or single bends as per your project design and needs. Also, the structure of HDPE pipes you get will vary depending on the slope direction and length of the field.

Which is Stronger PE or HDPE?

In comparing the strength of HDPE pipe vs PE, you have to consider that the making material, thickness, and general quality. The strength of the polyethylene pipe you get will depend on the type of PE pipe as per the range highlighted above.

Although you can bend the HDPE pipes to whatever form for their flexibility, they are quite durable. HDPE pipes are high impact resistant, and when you do proper jointing, they become stronger.

HDPE pipes also feature low thermal conductivity, so they can retain the normal operating temperatures despite extraneous factors. Using HDPE pipes allows you to control the condensation of fluids that require adequate insulation.

Unlike the ordinary PE pipes, HDPE pipes are rust-resistant and trigger internal pressure resistance for reliable use. The HDPE pipes maintain the initial flow capacity despite the prevailing environmental factors. You will, therefore, require little to no financial effort for maintenance purposes.

How many types of HDPE pipes are there?

HDPE pipes vary depending on the item the piping system is transferring and density. HDPE pipe sizes also vary in thickness, diameter, and length. The common types are HDPE 80 and HDPE 100.

HDPE 80 pipes transport gas raw materials, while HDPE 100 transfers liquid items like oil and water.

HDPE 100 pipes come with a higher density for robustness and thinner, rigid walls that offer operation stability. Since HDPE 100 pipes come with a higher strength ratio over HDPE 80, they are capable of working under high operating temperatures. HDPE 100 pipes are also resistant to sunlight, therefore, their durability is unmatched.

LESSO HDPE pipe offers a variety of products for you to choose from depending on your project needs.

Is the HDPE pipe safe for drinking water?

Yes. HDPE pipes are ideal for transferring drinking water as they protect water quality by being corrosion resistant and leak-free. HDPE pipe manufacturers use pressure-rated polyethylene material to make superior products.

HDPE pipes also have an NSF approval to use for portable water, hence, their application in the public drinking water services. Various US-companies trust HDPE pipes so much that they use HDPE-jars for storing and transporting milk.

How do you join the HDPE pipe?

In joining HDPE pipes, you can either opt for mechanical parts or use heat. Using screw connection through clamps or compression flanges also helps create stronger joints between HDPE pipes.

Unlike the traditional chemical jointing and rubber sealing in PVC pipes, joining HDPE pipes requires precision to avoid weak and leaking joints. Some of the common HDPE joining techniques include:

- extrusion welding

- butt welding

- socket welding

- electro-fusion welding

In all the cases, you apply heat to the joints until they are homogenous and strong-enough for reliable delivery. These HDPE pipe joining methods are safe for human health and the environment.

Fusion welding, in particular, eliminates the installation of anchors that restrain thrust as the gases or fluids move at high pressure.

Of the four HDPE joining methods, butt fusion is the most common since it is cost-effective and easier to carry out. Here, you use heat to stick to HDPE ends together, and bonding is necessary to make the joints stronger. You can also join the HDPE pipes with a backing ring and stud end.

During installation, ensure that the trenching leaves enough free space for welding. You also have to properly align the pipes to fill all the edges and allow for efficient welding. If you achieve the correct end-to-end HDPE pipe jointing, then the flow capacity will be high for smoother operation.

Remember, the jointing method you use will impact future excavations.

Various industrial sectors prefer HDPE pipes because they have a longer life expectancy. While their life expectancy is estimated at 50 years, some brands can go up to 100 years and more. Due to this durability, UV-resistance, and the affordability of HPDE pipes, various public projects rely on their innovation.

HDPE pipes are also great for environmental conservation as they preserve the fluids and gases in transfer from loss. The fused joints enhance the strength of the piping system, therefore, rendering the HDPE pipes leak-free. This feature and the corrosion resistance protect the fluids and gases in the piping system, which is a guarantee of quality.