■ Socket Fusion Joint for PP-R / Aluminum Composite Pipelines

Step 1. Deburring the connecting end of the pipe, use scissors or saw to smoothing and squaring the LESSO pipe end. And turn on the solvent weld machine (the solvent weld machine should be operated according to the specification strictly).

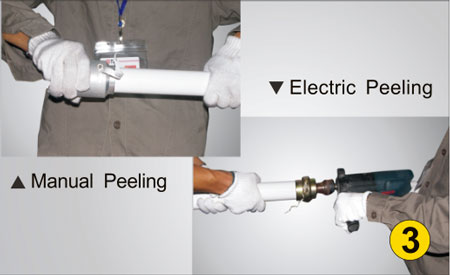

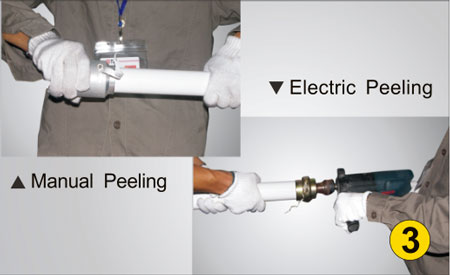

Step 2. Take out the corresponding peeling tool (generally use manual peeling tool for O 20-(P 40, use electric peeling tool for the diameter above.

Step 3. Insert the pipe into the peeling tool. Before the peeling tool starts to spin, hold the pipe against the blade. Mark the inserting depth on the pipe (the specific depths are showed in the chart below)

Step 4. Turn on the peeling tool, until peel to the mark line.

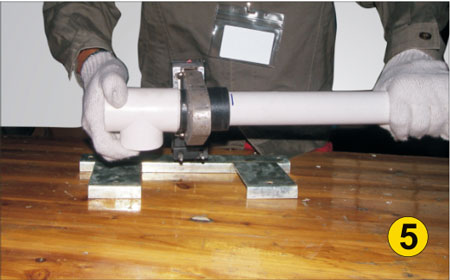

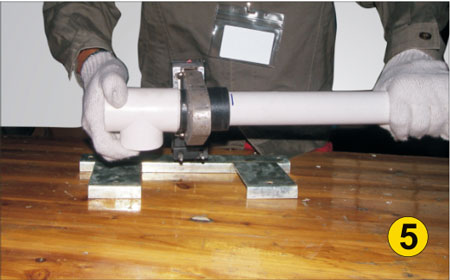

Step 5. Take out the pipe from the peeling tool. Insert the fitting into the solvent weld machine first, until the heating depth reaches 50% of the specific depth, then insert the pipe into the machine, makes the pipe and fitting insert into the bottom of the machine at the same time. The solvent weld temperature should be 260±10°C.

Step 6. Insert the pipe into the fitting quickly without rotation when reached the specific time. After the cooling period, the solvent weld joint is ready for use.

Inserting Depth and Solvent Welding and Cooling Time

Note: The environment temperature fits for this chart is 20°C. When the environment temperature in the construction site below 20°C, then prolong the heating time.

Installation Guide

The pipe can prevent to expand when its buried in the wall, floor or the templet. The pressure and the tensile stress can be absorbed without damage every materials. When the pipe contains isolation materials (the material should fit for the standards), these isolation materials should allow for more expansion.

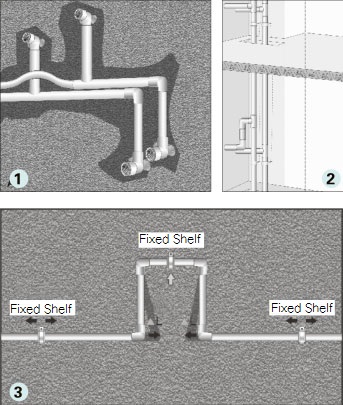

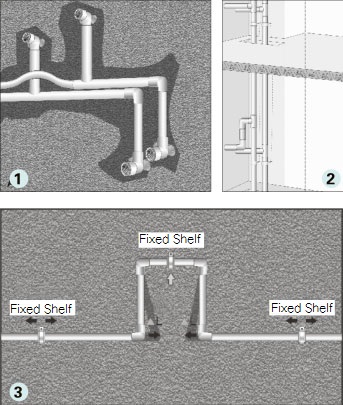

2. Install the pipe in the vertical well

The main vertical pipe can expand or shrink vertically between two floors if install fixed holders on both branch pipes near the main pipe. The distance between the two fixed holders should not exceed 3m. It can be used other methods to compensate the expansion, such as use the corner of branch pipe to compensate naturally.

3. Surface installation pipe

In some situation, use a kind of expand return circle (“U” return circle)to compensate the flexible length of the pipe. When install the fixed holders, pay attention to separate the pipe into each parts. Then the expansion power can be led to the needed direction.

General Regulations

1.1 Make the preparation before construction:

- Prepare all of the drawings and the related technique papers, hand over them to the construction party, make sure the requirements of the construction are specific.

- Prepare the construction program, pipe, fittings, cutting and peeling tools, special solvent weld machines and other needed conditions.

- Train the construction workers about the PP-R aluminum-plastic composite pipe installation technique.

- Temporary facilities such as construction site and the material storage area. Make sure that the electric power can fully supply the construction need.

1.2 Before system construction, the workers should know about the structure of the building, the design drawings, the construction program, the general performance of the PP-R aluminum-plastic composite pipe and fittings, the basic operation points. Forbidden to construct blindly.

1.3 When the temperature between the construction site and the material storage area has wide range, then put the pipe and fittings on the construction site for a certain while. Construct until the temperature of the pipe and fittings close to the construction site.

1.4 Check the appearance of the material and the joints carefully before system construction. Forbidden to use the pipe with obvious scratches, or pipe and fittings with oil or sundries.

1.5 Prevent the paints, asphalt or other chemical solvents to get touch with the pipe and fittings in construction.

1.6 For ensuring the unblocked and cleanness of the PP-R aluminum plastic composite pipeline, seal up the pipe end immediately when finish the installation or discontinue the construction.

1.7 Review the pressure grade (S series) and the type of the pipe before construction. Different types of PP-R aluminum-plastic pipes should not be mix installed. The mark on the pipe should face outside.

1.8 Take anti-frozen measurements when construct in winter.

Layout of Pipe

2.1 The indoor horizontal pipe should be laid in the ground, the indoor vertical pipe should be laid in the preserved groove. The indoor surface installation pipe should be installed after whitewash the building. Check weather the reservation location for the groove is right before installation.

2.2 Reserve the holes and grooves for the PP-R aluminum-plastic composite pipe when it crosses wall, floor or concealed buried in the all. When there’s no regulations about the dimension design, the following requirements should be executed:

- The dimension of the reservation hole should be 50~100mm greater than the pipe outside diameter.

- The width of the groove for the concealed bury-in-wall pipe should be dn+40mm, the depth should be dn + 20mm. The surface of the groove should be smooth. And the pipe should be fixed. The groove in the wall should be backfill dense by using cement mortar after the pipe passed the water pressure test.

- The vacancy above the pipe top should not less than 100mm.

2.3 The PP-R aluminum-plastic composite pipe should be laid according to the design drawings when supposed to concealed bury in the ground or the wall. Then mark the location and the direction of the pipe obviously. Forbidden to impact or peg the metal nail or other sharp objects on the pipe. If there were any changes in construction, there should be records on the drawings.

2.4 Set sleeve when the PP-R aluminum-plastic composite pipe crosses floor; the sleeve should at least 100 mm higher than the ground surface. Take waterproof measurements at the same time, When the pipe crosses the outer wall of the basements or underground buildings or roof surface, there must set metal sleeve to protect the pipe, and use rigorous waterproof measurements.

2.5 Preset metal sleeve when the PP-R aluminum-plastic pipe crosses the wall.

2.6 There should be no deformation along the axis when install the PP-R pipe. Forbidden to adjust by force.

2.7 Keep a certain protective distance between the PP-R aluminum-plastic composite pipe and other metal pipe when lay them paralleled, the net distance should not less than 100 mm. The PP-R aluminum-plastic composite pipe should be laid on the inner side of the metal pipe.

2.8 As regarding to the pipe buried in the floor; in the leveling layer or in the wall, make water pressure test on them or write down the final acceptance records of the concealed project before seal them up.

2.9 The horizontal PP-R aluminum-plastic composite pipe should has a water discharge gradient of 2%o~5%o.