PE Pipe is used around the world in a variety of projects. Since the 1950s, this type of pipe has offered significant advantages to project managers and it is rated highly in some applications over systems that use steel, cement or other materials. This article will explain what PE pipe actually is and how it is used.

What is PE pipe?

PE pipe is pipe that’s made of polyethylene (PE). These pipes are made of thermoplastic material, which is produced by the polymerization of ethylene. PE pipe is made via a process known as extrusion, so it’s easy to produce pipes of different sizes.

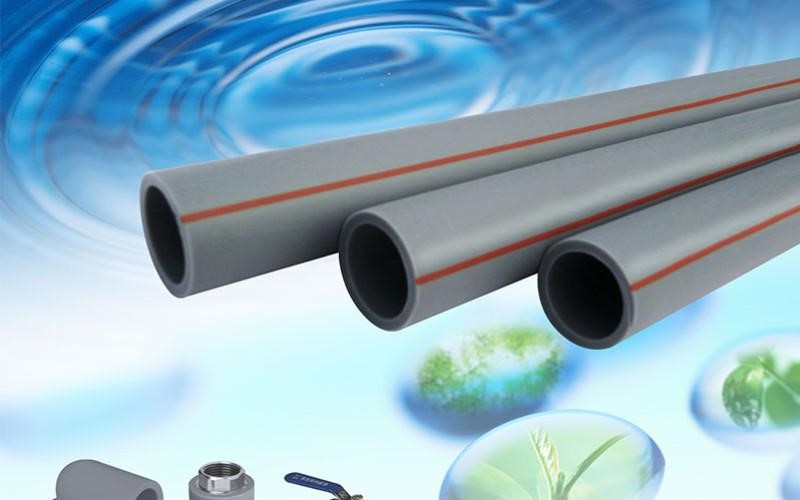

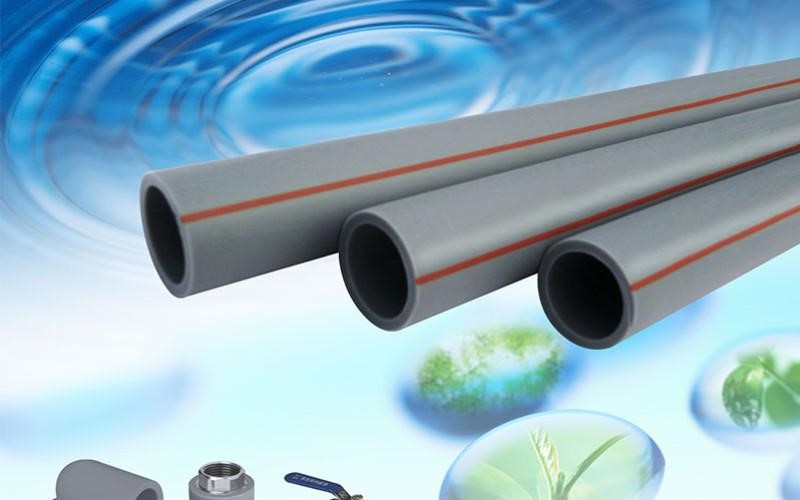

PE pipes stand up well to pressure, so they are used for various pressure applications and are manufactured in a variety of pressure classifications. You can obtain PE pipe with diameters of up to 1200 mm. The smallest have a diameter of around 0.5 inches.

You can purchase PE pipe in straight lengths or in rolled coils. Pipes with smaller diameters are usually sold in coils while those in straight lengths of up to 40 feet, usually have larger diameters. All of these pipes are lightweight and offer a fair degree of flexibility.

PE pipe is also known for its other qualities, such as toughness and longevity. This makes it a good choice in projects where hardiness is a requirement. PE pipes also resist chemicals, so they help to keep a supply from being affected by toxins.

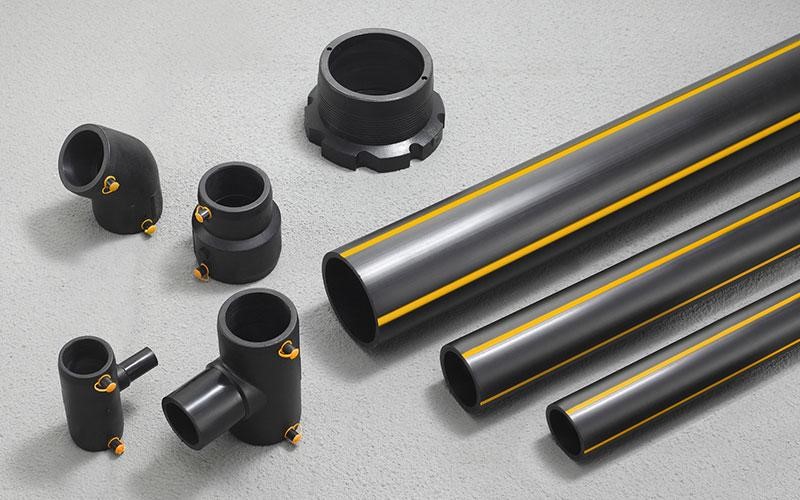

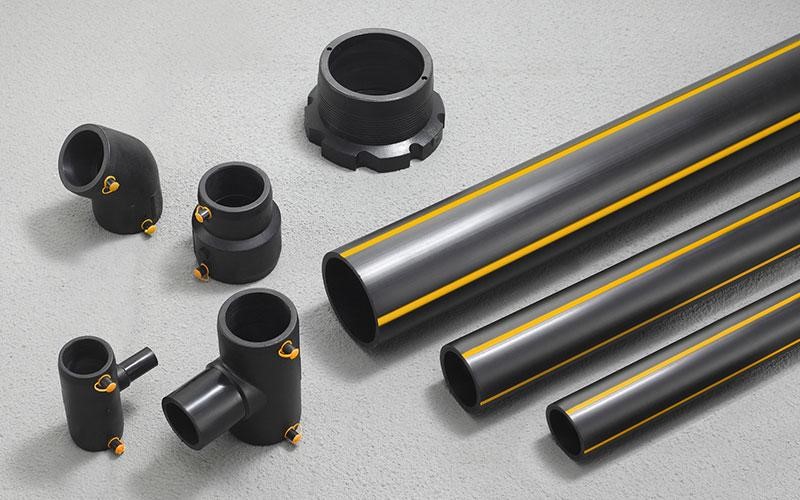

Versatile black pipes made of polyethylene are often seen being transported around or near water projects. These black PE pipes are produced by single extrusion. There are other pipes which are produced by double extrusion, which are also black but have a color striping.

Compared to other materials that are commonly used to make pipes, PE pipe has a low environmental impact. This is partly because of the way that it behaves around chemicals. It is not highly likely to react to chemicals in the environment and is not likely to leach any toxins into the soil when it is installed.

The Pressure Classes of PE Pipes

Polyethylene piping systems are resistant to pressure, so they are frequently used underground. They’re included in water supply networks in urban and rural communities. You’ll find them in sewage networks in cities or rural towns.

PE pipes are used to build drainage networks because of their pressure capabilities. When pressurized irrigation systems are being installed, these pipes offer unique benefits, such as longevity, that make them a popular choice.

Different pressure classes of PE pipes are used in each application. Each type of PE pipe is made to match a specific pressure designation and each of these pressure classes is known as a PN grade.

If you see an indication of its pressure on the pipe, that means you know how much pressure the pipe can withstand while it is filled with water. PN grades are given in bars, which is the standard unit of pressure. The grade is also based on water at a specific temperature, or 20 degrees Celsius.

As water heats up, it will start to exert more pressure on the pipe from within. This affects the amount of pressure that the pipe can withstand from outside. As an example, consider a pot with a cover. When the water in that pot starts to boil, enough pressure is exerted to tilt the cover. The water in a PE pipe can act in the same way.

When you’re selecting pipe for a project, keep in mind that the pressure measurement is given for relatively tepid water. If you want pipe that’s suitable for other applications, such as carrying water at a different temperature, you may need a different pressure grade of PE pipe.

According to European standards, the pressure grades are:

- PN 2.5

- PN 4

- PN 6

- PN 10

- PN 16

PN 2.5 corresponds to the smallest amount of pressure, which is 2.5 bar. If you select a PE pipe with this pressure rating, you can expect it to withstand a maximum pressure of up to 2.5 bar. The strongest pipe has a PN 16 rating. This means that it can withstand a maximum pressure of 16 bar.

What are the uses of PE pipe?

One of the main ways in which PE pipe is used, is for potable water systems. no one wants to drink water that is at risk of being contaminated with chemicals and this is where PE pipe’s relative inertness comes in handy. No toxins will leach from the pipe into drinking water, so the water supply will be kept safe while it is being transported through a network that is made with PE pipe.

PE pipe is also used to transport natural gas. Several people use natural gas for cooking and other applications. Natural gas cannot be stored in the way that some other gases such as propane, can. As such, it must be transported through a reliable network. These systems are built using durable PE pipes, which carry natural gas underground.

Since PE is very tough. It’s unlikely that the pipes will become damaged and leak natural gas, water or any other substance that they are transporting. Since polyethylene can be used at low temperatures without becoming brittle, this type of piping is good for climates that frequently are exposed to cold temperatures.

PE pipes can even be used for lawn sprinkler systems, since they will not easily be damaged if someone steps on them. They won’t start to leak if they are subjected to hot sunlight day after day in the summer and you will not need to replace your sprinkler system after cold weather. These pipes are also used for radiant floor heating, and even geothermal heat pump piping.

Summary

PE pipe allows project managers to save money during installation. LESSO has PE pipes for every type of project, which will stand up to different types of pressure. Trenchless technology can be used with Lesso’s PE pipes, avoiding the need for dangerous open trenches and reducing the level of disturbance that the general public experiences.