Table of Contents

Electrical conduit is an important component used in power systems to route and protect cables or wires. It can protect cables from physical damage and harsh environments, as well as help maintain electrical safety and facilitate cable management.

Choosing the right electrical pipe size is vital for the safety and efficiency of the entire system. Undersized conduits may lead to hazards such as cable overheating. On the contrary, oversized plastic conduit pipes may lead to waste and increased costs. Thus, in order to find the right size, one must consider several factors that influence their sizing and performance.

This article will explore how to select the electrical conduit pipe sizes to ensure the safety, compliance, and efficiency of electrical systems. Read on to learn more!

Risks of Improper Electrical Pipe Sizes

The size of the electrical pipes is vital, as it directly affects the functionality of the wires. Choosing the wrong size can lead to several risks. Some situations are as follows:

1. When the Size is Too Small

If the electrical pipe size is too small, it could cause the following issues:

- Tight contact between multiple wires can limit heat dissipation, leading to cable overheating and increasing the risk of electrical fires.

- Limited space makes wires hard to pull or replace, increasing maintenance difficulty and cost.

- Cause insulation damage, resulting in short circuits or electric shock risks.

2. When the Size is Too Large

On the contrary, if the size of the conduit is too large, it may lead to:

- Increased material and construction costs.

- A more complex installation process requires additional support and fixing measures.

- Pipelines occupy more positions, affecting the layout of other facilities.

Key Factors Influencing Electrical Pipe Size Selection

What affects electrical conduit pipe sizes? The key factors include the number of wires, cable filling capacity, conduit materials, installation environment, as well as relevant regulations and standards.

1. Number of Wires and Cables Fill Capacity

The cable fill capacity refers to the space that can be occupied by wires inside the conduit. It limits the number of wires they can contain. Staying within these capacities prevents overcrowding in the pipes and allows enough space for heat dissipation. To help with this, the National Electrical Code (NEC) provides a guideline on maximum fill percentages. For example, NEC stipulates that [1]:

- A single wire can only fill 53% of the conduit.

- Two wires can only fill 31%.

- If there are more than 2 wires in the conduit, the maximum filling amount is 40%.

2. Conduit Material

Metal electrical pipes usually have high mechanical strength and pressure resistance, so their wall thickness can be relatively thin while maintaining sufficient pressure resistance. For example, Electrical Metallic Tubing (EMT) and Intermediate Metal Conduit (IMC) generally have thin walls, which allows for more internal space, thus increasing cable fill capacity.

In contrast, non-metal pipes like electrical PVC pipes and HDPE pipes have comparatively thick walls, providing additional mechanical protection and preventing damage caused by environmental factors. Therefore, under the same size, the filling capacity of metal pipes will be higher than that of non-metal pipes.

3. Installation Environment

The installation environment of electrical conduits, such as indoor, outdoor, humid places, or places with corrosive media, will affect the electrical pipe sizes. For example, in humid or corrosive environments, it may be necessary to choose electric duct pipes with thicker walls to ensure sufficient mechanical strength and corrosion resistance.

Electrical PVC and HDPE conduits with thick walls are also widely used in outdoor and indoor environments due to their excellent moisture resistance, non-conductive properties, and flexibility.

4. Regulations and Standards

The design and installation of electrical pipelines must comply with relevant regulations and standards. NEC regulates the selection of appropriate electrical pipe sizes. They often include rulings on fill capacity, bending space, and protection against mechanical damage. These regulations ensure that wires can pass through pipes smoothly and there is sufficient space for operation inside the pipes, preventing safety risks caused by non-compliant cables.

Moreover, installers must familiarize themselves with their standard electrical regulations as they help meet safety requirements, prevent electrical hazards, and maintain compliance with regional codes.

How to Calculate the Size of Electrical Conduits?

Here’s a step-by-step guide on how to calculate the electrical pipe sizes:

1. Calculate the Number of Wires and Cross-sectional Area

List the total number of conductors that will be running through the conduit, including their size and insulation types. Then, use the NEC wire fill tables to find the cross-sectional area of each wire.

Next, multiply the number of wires by the cross-sectional area of each one. The sum will be the total area required for the wires.

2. Check Fill Percentage

As mentioned before, the NEC provides fill percentages depending on the number of wires in the pipe for electrical conduit. For example, if the pipe consists of two cables, the fill capacity should not be more than 31%.

3. Choose the Appropriate Conduit Size

To find the minimum electrical pipe size, divide the total cross-sectional area of wires by the allowed percentage of filling capacity.

For example, the cross-sectional area of two wires is 0.097 square inches, and the fill percentage for two wires is 31%. Then, the minimum required electrical pipe size would be 0.097/0.31 ≈ 0.313 square inches.

4. Consider the Bending and Pulling of Wires

In addition, if the installation involves frequently bending or pulling the wires, choose a pipe for electrical conduit slightly larger than the required size. This will allow for easier wire accommodation and reduce wire wear and tear.

Buy High-quality Electrical Conduits

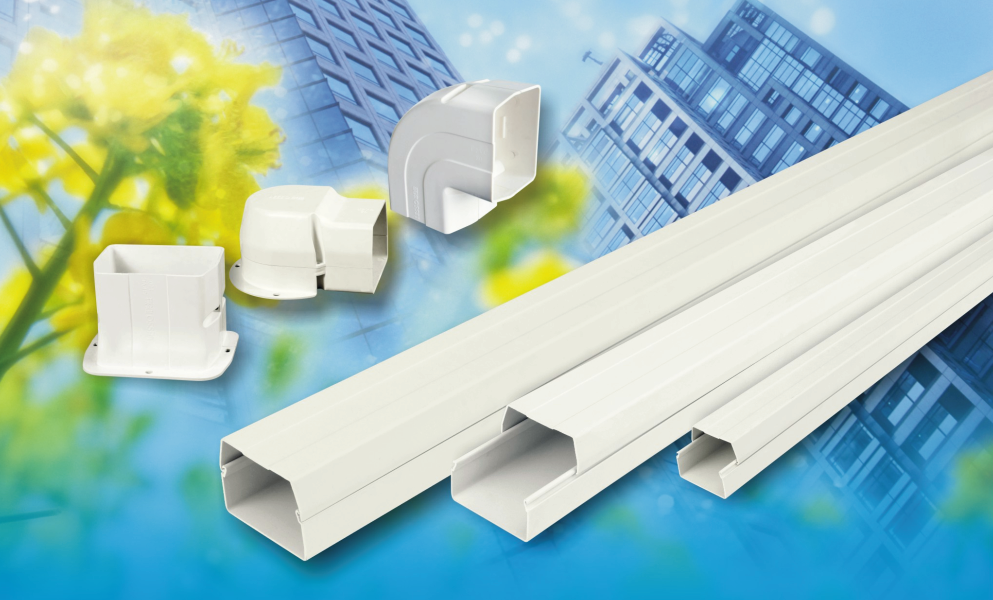

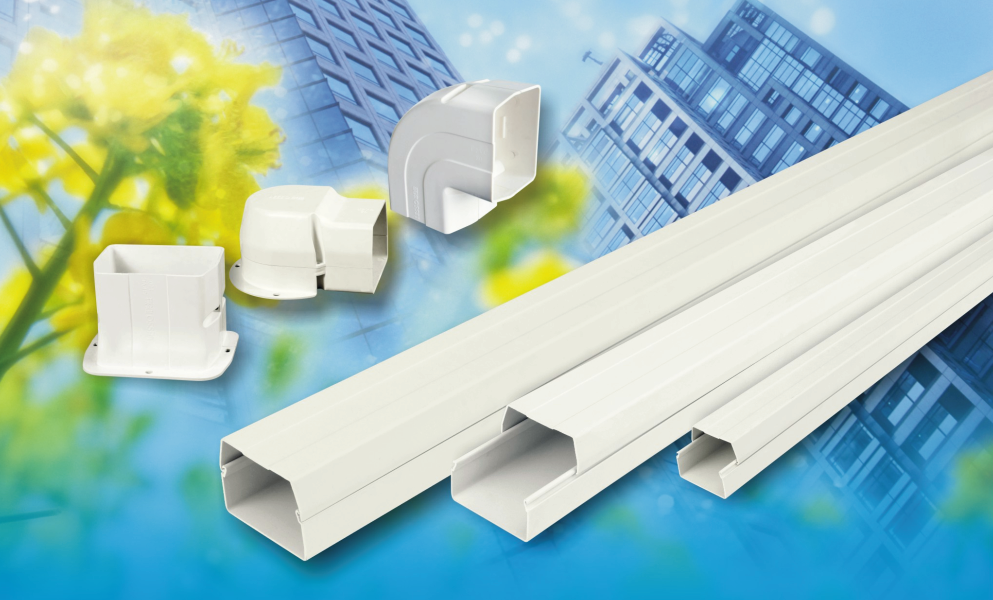

LESSO offers top-quality, durable electrical PVC pipes for different uses. Designed for both commercial and residential projects, our conduits go through extensive testing to meet industry standards. Our products include PVC conduit and fittings, PVC round-type wiring duct, PVC trunking and fittings, PVC multifunctional trunking and fittings, PVC air-condition duct, and galvanized steel conduit for wiring protection.

These pipes have good insulation, fire resistance, corrosion resistance, and impact strength, providing comprehensive protection for the safety of indoor and outdoor electrical systems. In addition, due to its lightweight and good breakage resistance, our electric duct pipes are easy to install and can flexibly adapt to various installation scenarios, such as exhibition halls, classrooms, residential homes, supermarkets, office buildings, material workshops, etc.

Conclusion

Choosing the correct electrical pipe size is vital for the efficiency of any wiring system. By considering factors like wire capacity, conduit material, installation environment, regulations, and standards, one can maintain a safe and long-lasting setup.

So, if you need high-quality electrical pipes for reliable performance, contact LESSO. Our business takes quality of life and customer satisfaction as the goal!

References

[1] National Electrical Code Explanations: Conduit Fill. Available at: https://www.codebookcity.com/codearticles/nec/conduitfill.htm (Accessed: 18 October 2024)