Table of Contents

Safe building practices for homes require encasing wire in electrical conduits. Protection from hazards that may damage the enclosed wire helps prevent fire and ensures efficient delivery of electricity.

A range of sizes, shapes and materials in conduit allows homeowners to select the most appropriate conduit for wiring or rewiring. The Buyer’s Guide serves as a reference for selecting the type of conduit that can serve specific purposes.

Understanding Electrical Conduits

Special types of tubes provide electrical conduits that route and protect the wires that deliver electricity to destinations inside residences. Made of metal, plastic, resin or fibers, electrical conduit maintains the integrity of the wiring it contains. Both rigid and flexible conduit can provide safe routing of electricity throughout a home, depending on the demands of each installation.

Electrical conduit keeps the wiring in place and protects it from external hazards. In addition, it creates a tidy appearance that enhances the aesthetics of a completed project. Electrical conduit enhances safety and efficiency in outdoor and outdoor installations. The National Electric Code (NEC) and local building codes provide guidelines for the proper use, placement and installation of electric conduit.

Types of Electrical Conduits

Wire size, the spaces that need electricity and the surrounding environment affect the choice of conduit for home installations. The varieties of conduit and fittings available in the market offer the proper solution for residential applications.

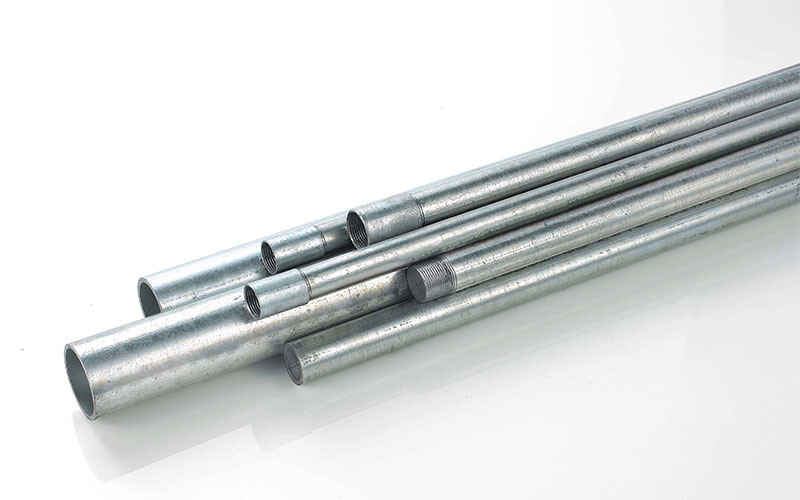

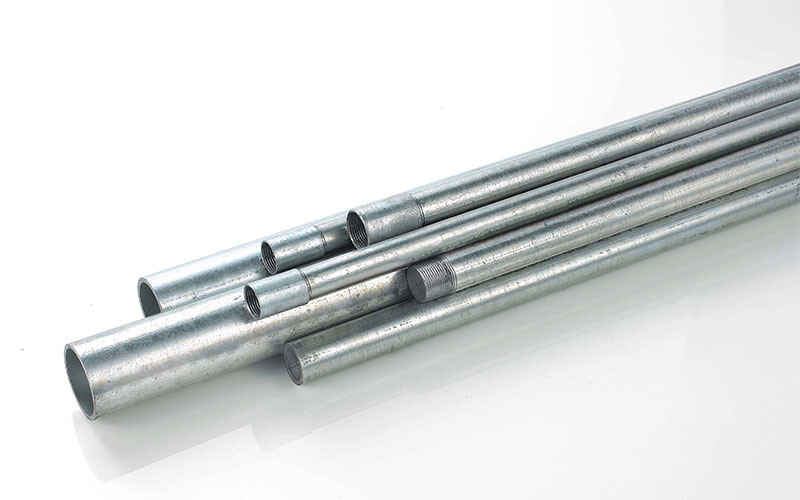

1. Rigid Metal Conduit

Various materials such as coated steel, aluminum or stainless steel can provide thick-walled, threaded tubing.

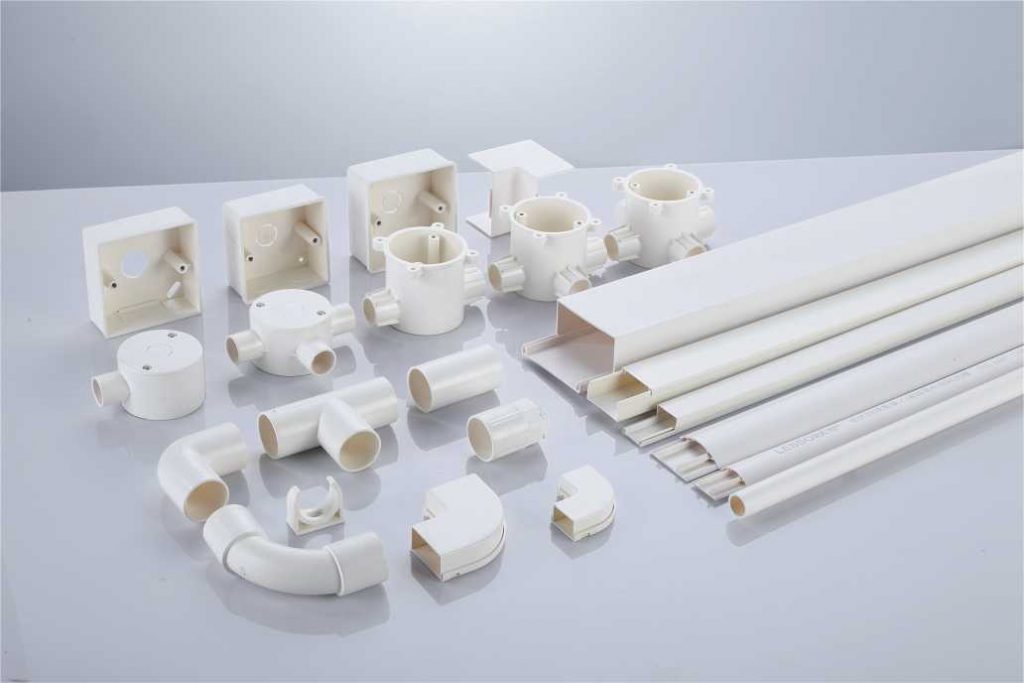

2. Rigid PVC and Thermosetting Resin Conduit

Straight wiring runs may use rigid PVC for protection from impact and moisture. Electric pipe that thermoset resins create may provide another type of conduit to protect electrical wiring.

3. PVC Electrical Conduit

PVC electrical conduit is a popular choice for both indoor and outdoor applications due to its resistance to corrosion, chemical damage, and physical impact. It is also non-conductive, making it an excellent choice for electric power, telecommunications, and cable installations.

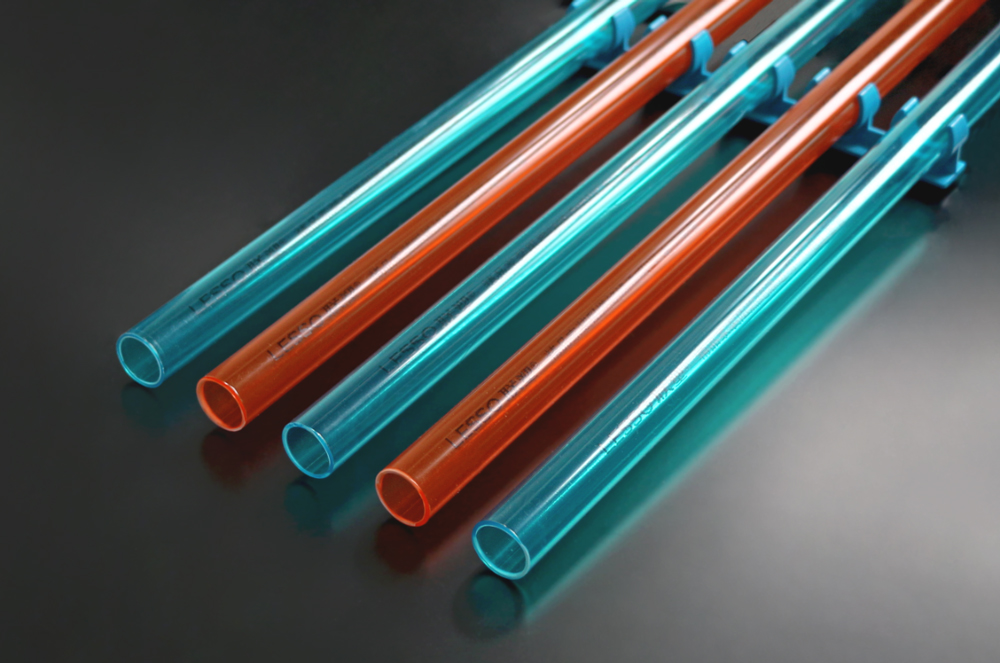

4. Transparent PVC Electrical Duct

Transparent PVC electrical duc is often referred to as clear PVC conduit. This type of conduit has the same properties as regular PVC conduit but with the added benefit of transparency. The installation process is visibly clear and intuitive, eliminating any confusion during installation.

Prior to burying the casing, customers find it more convenient to inspect the construction quality, ensuring the utmost safety of their home circuits. This meticulous attention to detail provides customers with a greater sense of assurance.

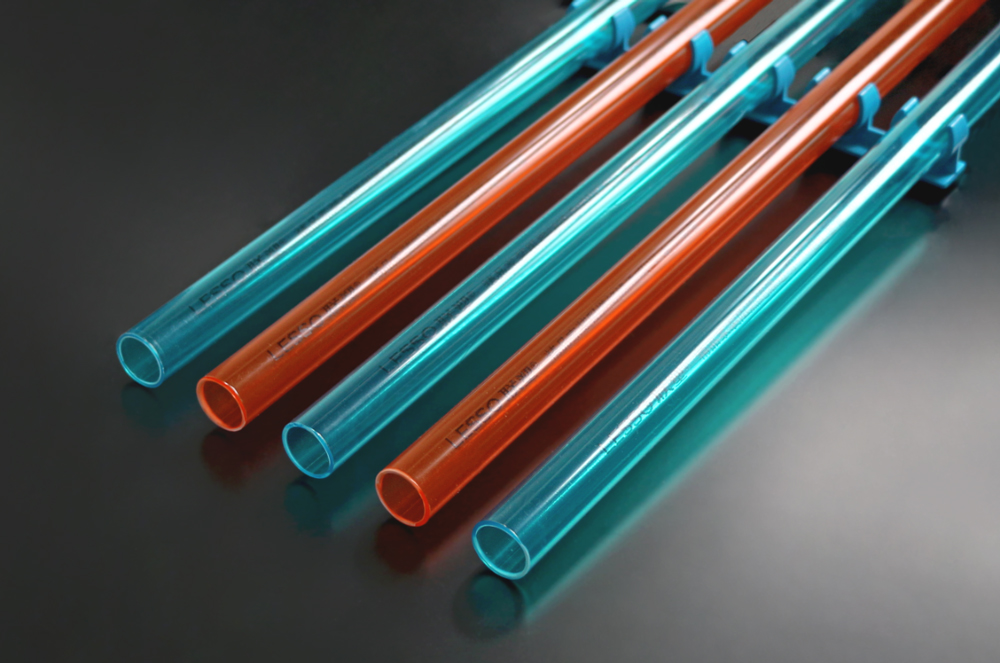

5. Red and Blue Transparent PVC Electrical Duct

Red and blue transparent PVC electrical ducts provide added convenience in distinguishing between regular lines and rapid screening lines. The installation process becomes clearer and more intuitive, avoiding any confusion during installation.

Additionally, the casing is buried, making it more convenient for customers to inspect the construction quality beforehand. This meticulous approach ensures the security of the household circuits, allowing customers to use them with greater peace of mind.

Factors to Consider when Selecting Electrical Conduits

Choosing the best conduit for home wiring projects depends on vital aspects that occur in different environments and locations in a home. The factors that deserve consideration can affect the completion of a successful installation.

1. Safety and Durability

The outer covering of electrical conduit protects wiring from accidental or purposeful damage. Safe and long-lasting, it prevents accidents to people and property.

2. Ease of Installation

Electrical conduit makes a new installation easy by providing a protected path for wiring. Rewiring becomes even easier when pulling the old wire out and replacing it with new.

3. Cost-effectiveness

Installation of a protected and reliable wiring system costs less than replacing one damaged by accident, abuse or external forces. A one-time investment in durable electric conduit does not need replacement. In addition, connectors and couplings can extend a run to room additions or changes that occur in remodeling.

4. Compatibility with the Wiring System

Wire size, the cross-section width of the wires and the number of bends in a run determine the size of electric conduit that makes it compatible with the wiring system.

5. Environmental Considerations

Durable and corrosion-resistant seal tight conduit or liquid tight conduit provides protection from UV rays, heat, cold, water, oxidation and other environmental forces. Electricity provides safe and clean energy, and electric conduit ensures its safe delivery across difficult terrains in all environments.

Conclusion

Rigid metal conduit uses metal for a thick wall electric pipe with threads. Rigid PVC and thermosetting resin conduit protect long runs from dampness and impact that can damage wiring. Flexible metal conduit (FMC) or Greenfield provides flexibility, strength and durability, and its coils let it fit around machinery but without protecting it from blows.

Liquid tight conduit with a flexible, metallic cover serves the same purposes as flexible metal conduit. LFMC has a nonconductive covering that resists moisture and UV rays. Liquid tight conduit and seal tight conduit resist moisture, acids and oils.

Homeowners need to consider vital concerns when choosing the best electrical conduits. Safety and durability of electrical conduit as well as the ease of installation in providing protection of electrical wiring for homes require an initial valuation.

The consideration of cost can make electric conduit the preferred choice. Compatibility with a home’s wiring system requires reliance on guidance in the NEC codes and standards. Homeowners may find the information in the NEC book and online.

LESSO provides the highest quality of PVC electrical pipe and fittings for electric wiring. Available in different pipe types, each product receives extensive testing that ensures quality and performance. For example, the PP-R Aluminum Composite Pipe delivers wiring for heating systems that include floor heating, wall heating and radiant systems.

In addition, central air conditioning systems perform well with the product. LESSO offers a line of PVC conduit for home decoration that protects and manages indoor electrical wiring. LESSO’s PVC electrical conduits for residences and industrial buildings lead the field in excellence and reliability.

Products include PVC round-type wiring ducts, trunking and fittings, multifunctional trunking and fittings, air-conditioning ductwork and galvanized steel conduit that provide wiring protection.

FAQ about Electrical Conduits

Rigid PVC conduit is a non-metallic conduit that is made of polyvinyl chloride. It is lightweight, easy to work with, and it is often used for underground wiring and in wet or humid environments. PVC conduit is also resistant to corrosion and chemicals, making it a good choice for applications where these materials may be present.

It is a durable and versatile conduit that can be used in a variety of applications, including indoor and outdoor wiring, as well as wet and dry environments. Here are some of the reasons why you might use rigid metal conduit:

- Durability: RMC is a very durable conduit that can withstand a lot of abuse. It is not easily damaged by impact or corrosion.

- Versatility: RMC can be used in a variety of applications, both indoor and outdoor. It is also available in a variety of sizes and types, so you can find the right conduit for your specific needs.

- Safety: RMC is a safe conduit to use. It is not flammable and it does not produce toxic fumes when it burns.

- Cost-effectiveness: RMC is a cost-effective conduit. It is relatively inexpensive and it is easy to install.

PVC thermoplastic cables are made of a material that can be melted and reshaped. This makes them easy to work with and install, but they are also more susceptible to damage from heat and chemicals. PVC thermosetting cables are made of a material that cannot be melted or reshaped. This makes them more durable and resistant to damage, but they are also more difficult to work with and install.

Recommend Reading

How Deep Should An Electrical Conduit Be Buried

Table of Contents Electrical conduits are the lifelines of modern infrastructure, seamlessly transporting power through a labyrinth of hidden pathways. Ensuring these vital channels are

Why Should You Use Conduit for Electrical Wiring?

When we talk about conduits, we are talking about pipes that are used to conduit electrical wiring through buildings. These conduits can be installed indoors