Lifespan refers to the length of time piping should remain in functional condition without needing repairs or replacement. Homeowners should be aware of the expected lifespan of their plumbing system so that they can stay ahead of any repairs or updates their home may need.

By being aware of a plumbing systems health, it can prevent leaks, sewer backups and other costly incidents.

Copper Pipes (50 - 70 years)

Red and brown in color, copper pipes have a life expectancy of fifty to seventy years. However, combined with heavy usage, the lifespan of copper pipes is closer to fifty years. Unfortunately, as copper pipes age, they become at risk for pin-hole leaks, which drastically reduces their lifespan.

This is because the lining of the pipe gradually becomes weaker and more prone to tiny leaks that can cause the pipe to need replacement.

Brass Pipes (80 - 100 years)

Brass pipes generally last longer than copper at eighty to one hundred years. This is due to their combined copper and zinc alloy, which results in a tough combination that can last for a century.

These pipes are not typically used anymore due to the fact that they contain trace amounts of lead. The quantity of lead may not be dangerous, but it should be taken into consideration.

Galvanized Steel Pipes (80 - 100 years)

The life expectancy of steel pipe is eighty to one hundred years and lacks the danger of leaving behind lead in the water. Steel pipes are dipped in zinc to provide them with a layer of protective coating.

This prevents corrosion and increases their lifespan. Galvanized steel pipes were most commonly found in 1960s America due to their long-lasting qualities and low cost. Later in their life expectancy they are prone to rusting, which makes them less durable than some other options.

Several significant studies predicted the lifetime of plastic pipes is more than 100 years.

As a commonly used type of plastic pipe, the life expectancy of PVC pipes is more than 50 years. Since they aren’t metal, there is no chance for corrosion and rusting over their lifespan. This makes them a great choice for homeowners who are worried about metal getting into their water supply.

Cast Iron Pipes (80~100 years)

Cast iron pipes have a lifespan of eighty to one hundred years and are built to withstand heavy use. But, like galvanized steel, they are also prone to rusting toward the end of their lifespan.

Cast iron pipe life expectancy made them a popular choice starting in the 17th century, all the way to the 20th century.

Factors That Change the Lifespan of Pipes

Location

Pipes on the bottom floor of a building struggle with the combined effects of cumulative use and corrosion

High Usage

When pipes are put through heavy use such as in an office building it shortens their lifespan. This cannot be prevented and should be taken into consideration when choosing a pipe material.

Lack of Maintenance

When pipes are not treated with routine maintenance, issues gradually build up and result in major failure.

Improper Installation

If pipes are not installed correctly, it will reduce their lifespan right away. Lack of pipe support, poor skills on the part of the installer, and contact with concrete all adds stress to the pipes throughout the building.

Improper Use

Forcing items that shouldn’t be in the pipe impact their lifespan. This could be flushing non flush-able materials down a toilet, pushing food items down the sink, or anything else that introduces something unnatural to the interior of the pipe system.

Corrosion

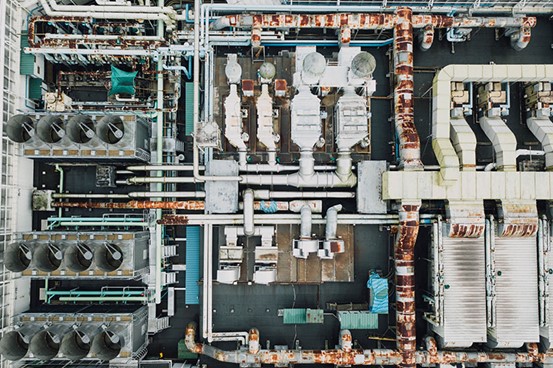

Most pipes will corrode overtime, however contact with certain cleaning substances can corrode a pipe from the inside out. If a building is by the ocean, contact with salty air can speed up outward corrosion.

Defects

Incorrect manufacturing can reduce a pipes life expectancy by more than half. The risks from these defects can include cracking, leaks, faster corrosion and more.

How to Prevent Pipe Repair and Replacement

The best way to prevent repairs and replacements of a pipe system is to conduct maintenance on a set schedule. By doing so, homeowners can catch issues before they develop into an issue that requires a plumber.

They can also prepare for the end of their pipes lifespan and prevent a serious failure.

Check Water Pressure

Different pipes suit for different water pressure. It is important for the pressure to not exceed the maximum number. If it does it causes serious strain on the pipes; if the number goes high enough the pipes can either leak, or burst entirely and cause damage.

If a homeowner discovers that their water pressure is too high and it won’t go down even after adjustment, it is important to contact a professional right away. They can come to the home and repair the water pressure before serious issues occur.

Seal the Joints

Sealing the joints on pipes can prevent a large number of future leaks. To seal the joints, it is important to tighten both the gasket and the joint. This doesn’t need to be done every time maintenance is conducted, but it is important nonetheless.

Tighten Fittings

Under the kitchen and bathroom sinks there are typically exposed pipes. While checking them, check for any moisture at the fittings. If there is, go ahead and tighten them. If the fittings have signs of corrosion or damage a professional should be called to replace the fittings and check for further damage.

China LESSO - The Highest Quality

Whether it is an office building, apartment building, high-rise or home, China LESSO pipes will last for decades. The company has over thirty years experience working in the plumbing industry and is China’s oldest manufacturer of piping.

Customers do not have to worry about shoddy workmanship, poor materials and short lifespans. Homeowners deserve the highest quality pipes possible and China LESSO delivers.

Recommend Reading

The Effects of Irrigation and Drainage Agricultural Pipes on Crop Yield

Table of Contents In the field of agriculture, water resource management is the backbone for achieving sustainable and efficient production. It not only affects the yield

10 Signs That Signal the Need for Pipe Replacement

A well-functioning plumbing system is the backbone of any living or commercial space. It can ensure efficient transportation of water resources, proper treatment of wastewater,