There is more than one option to store and keep cables organized during an installation. The containment systems you will select will be influenced by a variety of factors, including the type of building and wiring system. Moreover, the budget and other practical considerations within the building in question will also play a huge role.

With several options to choose from, there is a great need to take the time and study different options. Conduit and trunking are some of the most popular containment systems. Although most people assume both are similar, the reality is that they are different.

Keep on reading to discover the differences between conduit and trunking.

First Things First: What are Trunking and Conduit?

So what exactly are trunking and conduit? Read on to learn what trunking and conduit are.

Trunking

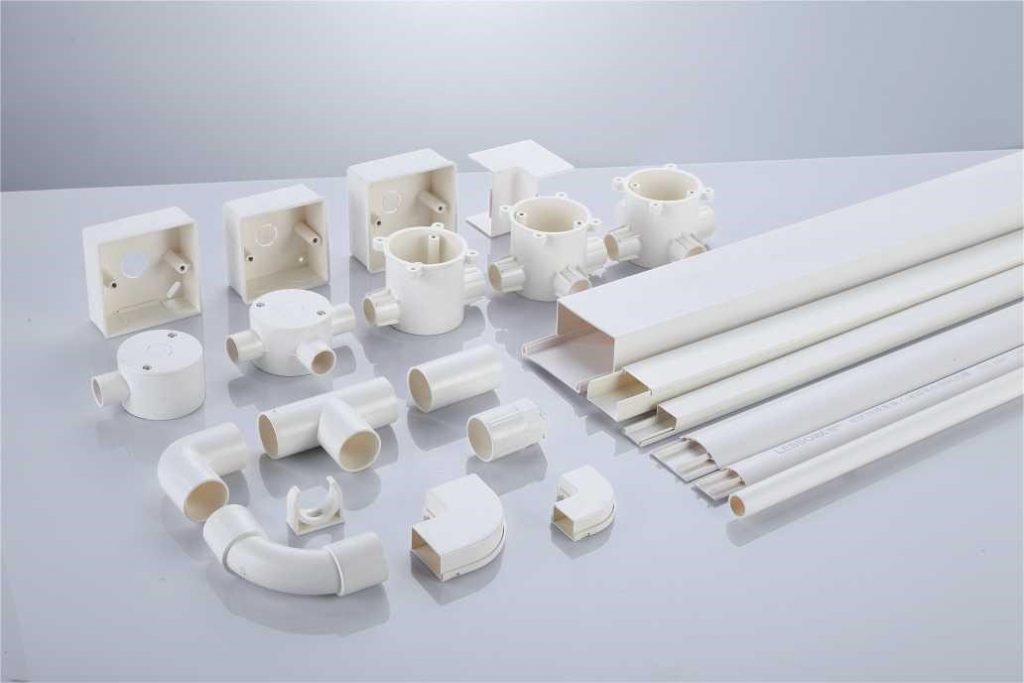

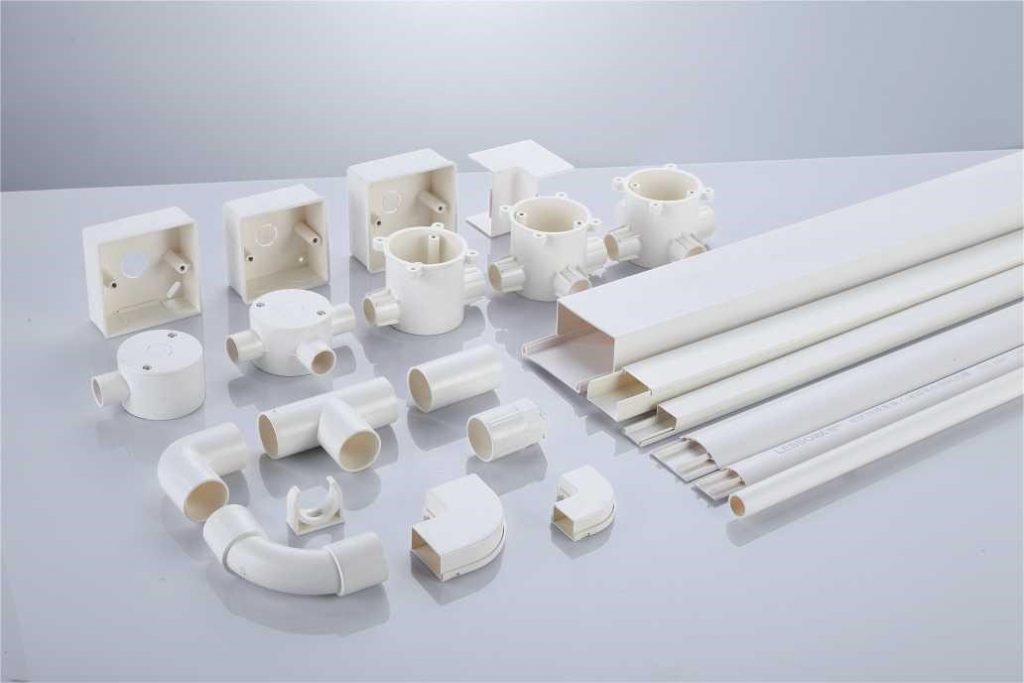

Trunking refers to an enclosure that protects cables. In most cases, it is rectangular or square in shape and has a lid that can be removed. Using trunking systems together with conduit systems offers more convenience and flexibility. While trunking is the framework of each installation, conduits cover the cables outside the trunking system all the way to the outlet boxes.

The good thing with trunking is that it allows the installation of an extension. You only need to drill a hole on the preferred side of the trunking and attach the new wiring through the conduit to the installed trunking system.

Various Types and Sizes of Trunking

Now, there are various types and sizes of trunking. Learning about the different options is essential. Below are popular trunking types:

Cable trunking. In this type of trucking system, the lid is kept in place by turnbuckles.

Bus-bar trunking. In this trunking type, copper or aluminum is used to protect the components.

Lighting trunking. This trunking type is installed with the opening facing downward. It is commonly used for luminaries.

Multi-compartment trunking. This type of trunking system allows for the separation of different services and voltages.

Trunking systems are also available in a variety of surfaces. Discover the most

- Plastic like PVC

- Stainless steel

- Silver enamel on zinc coating

- Grey enamel on zinc coating

- Hot dipped galvanized coating

Typical Trunking Sizes

Trunking is available in a range of sizes. However, the following are the most common trunking sizes:

- 50mm x 50mm

- 75mm x 50mm

- 75mm x 75mm

- 100mm x 50mm

- 100mm x 75mm

- 100mm x 50mm

- 100mm x 100mm

- 150mm x 75mm

- 150mm x 100mm

- 150mm x 150mm

- 200mm x 100mm

- 225mm x 150mm

- 250mm x 150mm

- 300mm x 250mm

Conduit

Now that you know what trunking is, let us discover more about a conduit. Simply put, a conduit is a pipe, channel, or tube that covers insulated conductors. It protects the outer sheath of a cable from mechanical damage. The good thing with a conduit installation is that it can be rewired or changed at any time. Like trunking systems, there are various conduit types. Find out about different types of conduit below:

- Steel

- PVC

- Stainless steel

Steel Conduit System

This type of conduit system is manufactured according to the specifications provided by the British Standards Institute. The most popular type, hot dip galvanized steel features a welded seam and heavy gauge, making it the best option for damp and external installations. Steel conduit is the go-to option for many users because it is affordable, reduced risks, easy to rewire, and can be used as Circuit Protective Conductor (CPC). However, steel conduit system is susceptible to corrosion, and can be quite costly.

The best way of bending steel conduit is using a bending machine. However, a bending machine is not suitable for bending steel conduits with more than 32mm diameter. Instead, portable ratchet benders are used.

PVC Conduit

PVC conduit is popular because it can withstand acids, alkalis, pests, fungi, bacteria, aggressive soils, and rodents. What is more, PVC conduit can be installed under sea, concrete, plaster, and lime without wearing out.

Hot bending is usually used to bend PVC with more than 25mm diameter. When hot bending PVC conduit, the right bending spring.

What are Trunking and Conduit Used for?

Trunking systems are used in a variety of applications, including industrial and commercial applications. For instance, lighting trucking is usually used for fluorescent fittings used to light a large room, while cable trunking is installed on the walls of buildings. Multi-compartments are necessary for cabling needs required in close stations. Conduit systems are then used to provide needed outlet points.

What is the Difference between Electrical Conduit and Trunking?

Electric conduit is a tube made of metal or plastic that protects and routes the electrical wiring of a structure or building. It helps to protect the electric wiring from moisture and mechanical impact. Another benefit of the electric conduit is it ensures safety since it will be easy to withdraw the conductors that are currently there are replace them with new ones. Electric conduit is also essential since it is reliable, durable.

On the other hand, the electrical trunking system consists of a rigid piece of PVC, copper or aluminum and is used where different electrical cables come together since it helps to carry a compound current. Electrical trunking system ensures safety from dust and humidity. It also prevents damage of the cable insulation and is long lasting. Examples of the trunking options include the small fiberglass cable and PVC coated.

When to Use Trunking or Conduit?

Conduit system is ideal for installations in external and damp environments. It protects the conductors from harmful substances, including moisture and chemicals. Moreover, it is the best wiring systems for buildings that will undergo changes in the future since it can be altered and removed easily. It can be submerged in water. Installation companies can also use metal conduit systems to minimize electromagnetic interference.

Trunking system is ideal for the distribution of high currents in buildings, equipment, and switching yards. This installation type distributes current when multiple electrical cables are used.

Final Thoughts

When you need trunking and conduit systems for electricity or commucation system protection, be sure to check China LESSO.

Recommend Reading

How Much Do You Know About PVC Conduit

Conduit is crucial for keeping your home safe from potential threats. There are different types of conduits suitable for different applications. However, PVC conduit is

Ultimate Guide to PVC Pipe

Although working with plastic pipes is easy, you still need plastic pipe guides to get the best results. As PVC has replaced most alternatives that