Table of Contents

One of the most important and often overlooked features of any home is the plastic piping used to carry water, heat, and electricity. There are several different types of material that can be used, but two of the most popular are PVC and CPVC.

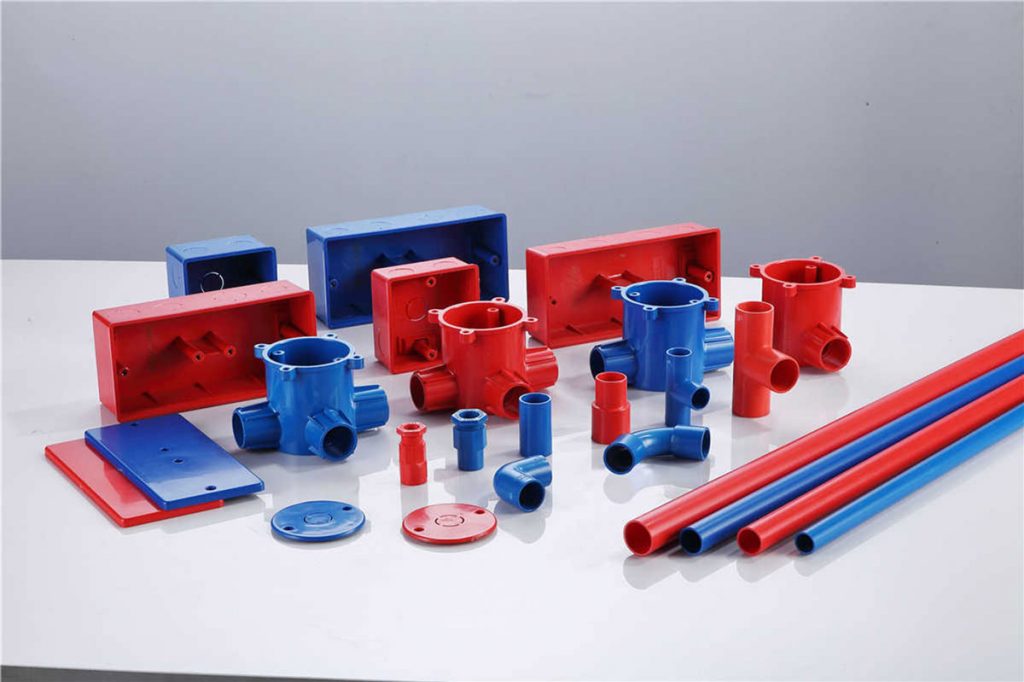

LESSO makes high-quality versions of both products, with each type being the best option for different situations and home layouts. PVC is less expensive and has been used for decades, while CVPC is the preferred option for underground electrical conduits.

Let’s take a look at CPVC vs PVC, how to tell if a pipe is PVC or CPVC, and which product is best for various applications.

What is CPVC?

CPVC stands for “chlorinated polyvinyl chloride” and is similar to PVC, but it has been treated with chlorine to enhance its natural properties. For pipes that carry water, the chlorine will have no effect on the way that water tastes when it comes out of the faucet.

CPVC is a cream-colored plastic piping material that is in many ways an upgraded version of PVC, although there are some applications where the latter would be preferred. It is highly pressure-resistant and capable of handling temperatures up to 200 degrees Fahrenheit.

Characteristics of CPVC

Like traditional PVC, CPVC is a thermoplastic that is generally used as a conduit for things such as water, other liquids, or electrical wiring. It has been used for home plumbing since its invention in the 1960s.

This newer form of piping has many advantages, including its increased flexibility and ability to withstand higher temperatures than standard PVC piping. For these reasons, it is very popular with underground electrical conduits.

It can protect the electrical wiring from soil erosion or other potential dangers and make sure the wires are routed in the most efficient manner possible.

What is PVC?

PVC is another plastic piping material which stands for polyvinvyl chloride that has been used for decades as a replacement for copper or other forms of metal piping, which is prone to rusting and corrosion damage, unlike PVC.

Characteristics of PVC

PVC is a white pipe that can withstand temperatures of about 160 degrees Fahrenheit and is commonly used for plumbing and other domestic applications. It was first discovered in 1872 but it took decades until scientists realized its advantages over traditional metal pipes.

It is known for its chemical and fire-resistant properties. When PVC is exposed to a flame or other heat source, it produces hydrogen chlorine gas, which prevents the pipe from catching fire.

Differences Between CPVC and PVC

The main difference between PVC and CPVC is the primary application for each type. CPVC is now preferred for plumbing and PVC is generally used for consumer goods, although there are exceptions in each case.

Although they are essentially made of the same materials, CPVC has been treated with chlorine, which enhances the natural properties of the material and allows it to withstand higher temperatures, in addition to increased flexibility.

The two are have different sizes. PVC is measured using the IPS (Iron Pipe Sizes) measurement, while CPVC generally uses CTS (Copper Tubing Sizes), although some CPVC does use IPS. Due to the size difference and other factors, the materials cannot be joined together, meaning each application will require one or the other.

When deciding between CPVC vs PVC, the other major factor to take into consideration is the additional chlorine content found in CPVC. Some chemicals, particularly ammonia, are highly reactive with chlorine and should not be used in CPVC pipes.

How to Identify CPVC and PVC?

As the two can be pretty similar in appearance, consumers will want to know how to tell if a pipe is PVC or CPVC. The easiest way to differentiate between PVC and CPVC is color: PVC is white and CPVC is a lighter cream or beige color.

The two also generally have different sizes, with some CPVC pipes being larger than PVC, although this is not always the case. CPVC will also have greater flexibility than its more rigid counterpart.

If the pipe still has visible markings, it will often say the manufacturer’s name, the dimensions of the pipe, and whether it is PVC or CVPC. Some of the latter type also feature a yellow stripe lengthwise down the side, although not in every instance.

Special Focus: CPVC in Underground Electrical Conduit

CPVC is preferred over PVC for underground electrical conduits for several reasons. First, its increased flexibility allows for shorter distances when routing the wires. It also can withstand higher temperatures and reduce maintenance costs over time by lasting longer than standard PVC.

To address these issues, many electricians and homeowners are turning to CPVC as a preferred alternative for underground electrical conduits.

They also find that the wires take a longer path than is necessary, due to the PVC’s relative lack of flexibility. By using LESSO CPVC pipes instead, the wires can be better routed and better protected from acids in the soil.

Even better for the homeowner, the new pipes will last years longer than the old PVC or copper pipes, which will result in lowered maintenance costs over the home’s lifetime.

Conclusion

Due to its increased chlorine content, CPVC holds several advantages over regular PVC, including the ability to handle higher pressures and temperatures, increased flexibility, and a significantly longer lifespan.

For projects that require higher temperatures or involve underground electrical conduits, you may want CPVC instead of PVC. For projects that involve chemicals that could potentially react to chlorine, standard PVC is the preferred option.

For all of your home or industrial piping needs, whether it’s PVC, CPVC, or a different material, LESSO has the products you need at prices you’ll love. Check out their website or visit a fine retailer near you today!

Recommend Reading

The Lifespan of PVC Pipes: What You Need to Know

Table of Contents Why are PVC pipes so popular? PVC pipes are largely used because of their strength, durability, and corrosive-resistant features. This makes them

PVC vs ABS vs PEX: The Ultimate Guide to Sewer Line Materials

Table of Contents The sewer line materials you select for your residential plumbing upgrade, home improvement project, or piping repairs should be of the highest