Table of Contents

Electrical conduits are the lifelines of modern infrastructure, seamlessly transporting power through a labyrinth of hidden pathways. Ensuring these vital channels are safely tucked away beneath the surface is crucial for the well-being of both the electrical system and those who interact with it. With that in mind, we prepare this comprehensive guide for you to navigate the depths of electrical conduit installation. Now, let’s begin our quest to master the art of burying electrical conduits!

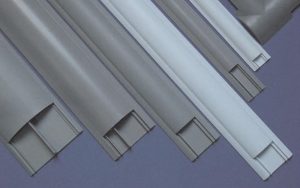

Types of Electrical Conduits & Their Applications

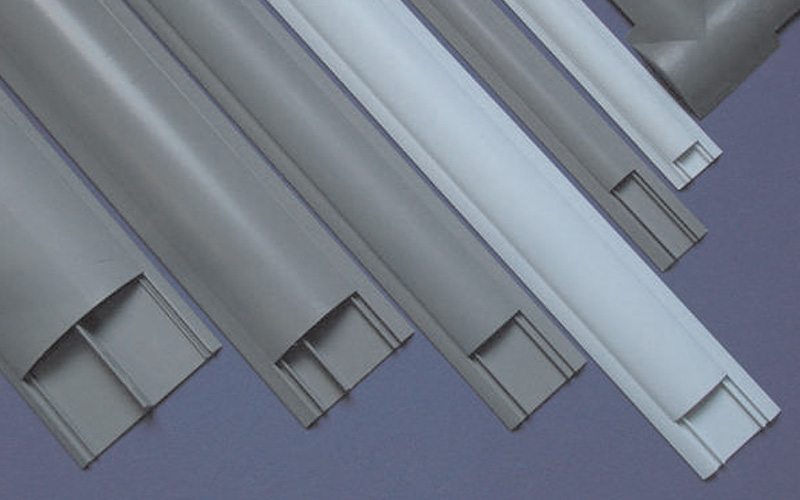

Electrical conduits can be separated into two broader categories of metal and non-metal electrical conduits. There are different types in each category. The various types of metal electrical conduits include:

1. Rigid Metal Conduit

2. Galvanized rigid steel

Galvanized rigid steel is used in outdoor and indoor applications. It’s made with a durable steel, which allows it to have high UV stability and impact resistance. Because of its heavy weight, it’s expensive and difficult to install.

3. Intermediate metal conduit

Intermediate metal conduit has a slightly lower weight than rigid metal conduit but is solely used in outdoor spaces. It’s relatively affordable and can be coated. While this type of underground electrical conduit accommodates more wire fill than the alternatives, it’s more likely to be damaged.

4. Electrical metallic tubing

Electrical metallic tubing comes with thin walls and isn’t threaded. It is made from coated steel and is often used in industrial and commercial applications.

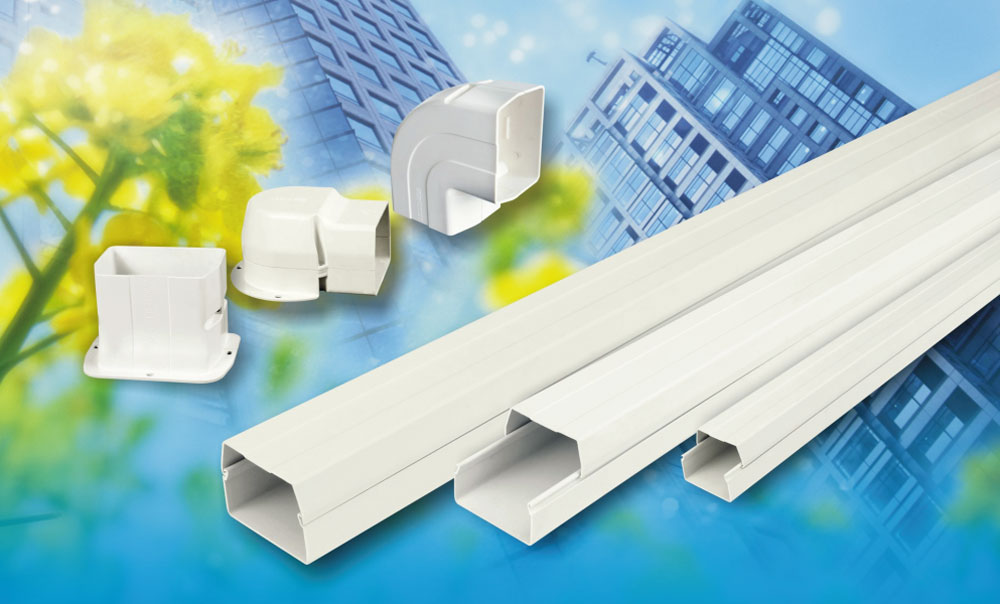

5. PVC Conduit

The common non-metal electrical conduits include PVC conduit and PVC-C underground power cable ducts.

PVC conduit is threaded and comes in numerous thicknesses. It’s a lightweight material that shouldn’t be placed in direct sunlight because of its low UV stability. The material should be mounted as well. If the environment where the PVC is installed is too hot, it could deform.

The PVC-C underground power cable duct is widely applied in municipal works. It is quite flexible and has impressive resistance to high temperatures and chemicals.

Required Depths for Different Types of Electrical Conduits

How deep does the electrical conduit need to be buried? In fact, the required depth for burying underground electrical conduits varies depending on the type of conduit, the nature of the installation, and the applicable building codes and regulations.

1. Rigid Metal Conduit (RMC) and Intermediate Metal Conduit (IMC)

RMC and IMC are both robust and durable, providing excellent protection against physical damage. When used for direct burial, the National Electrical Code (NEC) requires a minimum cover depth of 6 inches for residential installations and 18 inches for non-residential installations.

2. Electrical Metallic Tubing (EMT)

EMT is not typically recommended for direct burial due to its thinner walls, which offer less protection against physical damage. However, if EMT is permitted for direct burial in your local codes, the NEC requires a minimum cover depth of 18 inches for both residential and non-residential installations.

3. Flexible Metal Conduit (FMC) and Liquid-Tight Flexible Metal Conduit (LFMC)

FMC and LFMC are generally not recommended for direct burial. Instead, they should be encased in concrete or installed within another suitable conduit system to provide adequate protection.

4. PVC Electrical Conduit

PVC electrical conduit is often used for underground installations due to its resistance to corrosion and moisture. It is one of the most frequently-used electrical conduits. According to the NEC, PVC conduit requires a minimum cover depth of 18 inches for residential installations and 24 inches for non-residential installations.

Please note that these guidelines are based on the NEC, which may not apply to your specific location. It is crucial to consult your local codes and regulations, as well as any additional requirements set forth by your utility company, to ensure compliance and safe installation.

Additionally, if the conduit installation is located under a road, driveway, or other areas with vehicular traffic, the required burial depth may be greater to provide extra protection against damage. Always verify the appropriate depth requirements for your specific situation before proceeding with the installation.

When Should You Use Electrical Conduits?

Electrical conduits are essential for providing a protective pathway for electrical wiring, ensuring the safety and reliability of an electrical system. In this section, we will explore four common situations where electrical conduits should be utilized to maintain the integrity and safety of your electrical system.

1. When Running Electrical Wiring Through Ceilings or Walls

Electrical conduits are crucial when installing wiring inside walls or ceilings, as they protect the wiring from physical damage, such as punctures and abrasion. Conduits also help maintain the separation of electrical cables from insulation materials and prevent contact with other building components. This separation reduces the risk of electrical fires and ensures that wiring remains accessible for maintenance and repairs.

2. When Running Electrical Wiring Outdoors

Outdoor electrical installations are exposed to various elements, such as weather, moisture, and temperature fluctuations. Electrical conduits provide protection against these elements, helping to prevent damage and degradation of the wiring over time. Additionally, conduits guard against damage from external sources, such as accidental impact, rodents, or vandalism, maintaining the integrity of the electrical system.

3. When Running Electrical Wiring in Damp or Wet Areas

In wet or damp locations, such as basements, bathrooms, or commercial kitchens, electrical conduits are necessary to protect wiring from moisture ingress. Conduits designed for these environments, such as PVC, ensure that moisture does not compromise the electrical system and reduce the risk of electrical shorts, corrosion, and other moisture-related issues.

4. When Running Electrical Wiring Through Hazardous Areas

Electrical conduits are essential when running wiring through areas with potentially hazardous conditions, such as flammable or explosive atmospheres. In these situations, conduits designed to prevent the ignition of surrounding gases or vapors, such as explosion-proof conduit or sealed conduit systems, are required. These specialized conduits help maintain the safety of the electrical system and reduce the risk of accidents in hazardous environments.

The Role of Electrical Conduit

Electrical conduits serve several important functions in electrical installations. These include:

Protection:

Conduits shield electrical cables from physical damage caused by impact, abrasion, and environmental factors. They also safeguard cables from moisture, rodents, and other potential threats.

Organization:

Conduits help organize and separate multiple cables, reducing the risk of cable entanglement and making it easier to manage and maintain electrical systems.

Safety:

By enclosing electrical wiring, conduits prevent direct contact with live wires, reducing the risk of electrical shock and potential fire hazards.

Common Mistakes to Avoid When Burying Electrical Conduit

When burying electrical conduits, it is crucial to avoid common mistakes that could compromise the integrity and safety of your electrical system. Here are some key pitfalls to watch out for:

Incorrect burial depth

Failing to bury conduits at the appropriate depth can expose them to damage and violate local codes and regulations. Always consult local requirements and adhere to the recommended burial depths for the type of conduit being used.

Inadequate conduit support

Conduits must be properly supported during installation to prevent sagging, collapse, or damage.

Ignoring expansion and contraction

Temperature fluctuations can cause conduit materials to expand and contract. To prevent damage, use expansion joints or flexible connections when necessary, and allow for adequate space around the conduit to accommodate movement.

Improper sealing

In wet or damp locations, conduits must be sealed properly to prevent moisture ingress. Make sure to use suitable conduit fittings, gaskets, or sealants to maintain a watertight installation.

Conclusion

In this guide, we have delved into the different types of conduit material, explored their perfect depth for burying, and learned the role electrical conduit plays and why we should use it. We have also discussed the mistakes you can avoid when burying electrical conduits.

LESSO electrical conduits provide long-lasting, reliable performance in various applications with remarkable durability and resistance to environmental factors. Trusting in LESSO means investing in a safe and efficient solution for all your electrical installation needs.

FAQ about Electrical Conduit

Burying electrical conduit at the proper depth helps protect it from damage caused by external factors such as heavy machinery or landscaping equipment. It also prevents accidental contact with the conduit and its contents, which can result in electrical shock or other hazards.

The depth at which electrical conduit should be buried depends on a variety of factors, including the type of conduit, the location of the installation, and the local building codes. As a general rule, conduit should be buried at a depth of at least 18 inches, but in some cases, it may need to be buried deeper.

There are several types of electrical conduit, including PVC (polyvinyl chloride), steel, aluminum, and flexible conduit. Each type has its own advantages and disadvantages, and the choice will depend on the specific needs of the installation.

Recommend Reading

The Varieties of Electrical Conduits

Table of Contents If there is any development that has helped to change the way we live our lives, it’s the advent of electricity. Electricity

Why Should You Use Conduit for Electrical Wiring?

When we talk about conduits, we are talking about pipes that are used to conduit electrical wiring through buildings. These conduits can be installed indoors