Table of Contents

What is Electrical Conduit?

Simply, electrical conduit are the materials used to help protect and preserve the conducting wires within an electrical system.

Aside from helping to keep wiring organized and protected from anything that could cut or break the connection, conduit also helps to provide a fire preventative and reducing strategy, an important consideration anywhere that electrical systems are being installed.

Advantages of Electrical Conduits

There are a variety of cost-cutting measures that you can use that don’t require the use of conduit, such as stapling wires to framing as a means of keeping it out of the way. While cost-effective, these measures don’t offer the protective advantages that conduit offers.

One of the protective features that conduit offers, aside from impact and fire protection, is protection from moisture or chemical vapors. Moisture is electricity’s enemy and the potential cause of short circuits or inoperative wiring. Although all wiring should be insulated, cabled or spliced wires benefit from the extra protection that conduit offers.

Metal conduit can also offer a protective barrier against electromagnetic interference, a valued asset for select circuitry or power cables. Conduit with proper fittings prevents the flow of flammable gases and vapors, adding extra fire protection.

For buildings that will require future renovations or structural changes, or even during a regular building installation, conduit makes it much easier to store and install wiring so that it is not splayed within a work site, increasing the possibility of potential damage to wiring. The smooth surface of conduit makes it much easier to slide wiring into and out of spaces, especially compared to fish tape or other means of locating and moving electrical lines.

Certain conduit, combined with the proper cable, allow wiring to be situated within concrete areas or even embedded underground, extending the wiring locations and dimensions for a specific project.

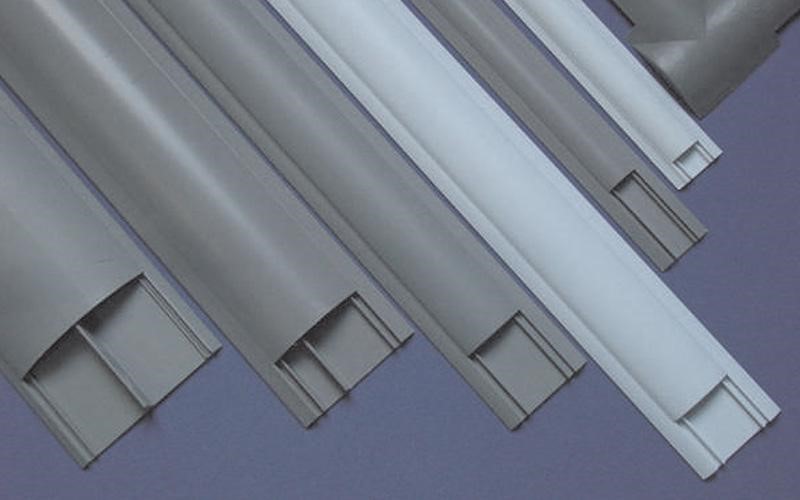

Conduit comes in a variety of styles and sizes to suit a variety of wire types, installation locations and installation features. The only special consideration when installing conduit are limitations in bending, as conduit can’t have more than 360 degrees of bending within one segment; for that, special electrical fittings are required.

Different Types of Electrical Conduits and its Applications

There are a variety of electrical conduit types for a variety of different applications:

- Rigid Metal conduit is made of heavy-duty galvanized steel with threaded fittings to allow different sections to be screwed into each other. It is the sturdiest, and most expensive, conduit type and is usually used outdoors, for connecting panels as well as running cables through walls.

- Intermediate Metal conduit is slightly lighter and thinner than Rigid metal conduit, though it is often used in the same applications.

- Electrical Metallic tubing can be made of either galvanized steel or aluminum and is thinner and lighter than intermediate metal conduit. It attaches to other pieces via compression fittings and is usually used in exposed indoor wiring because it is easier to bend and is more aesthetically pleasing.

- Flexible metal conduit is ideal for indoor wiring that requires substantial bending, such as in an attic or with water heaters, as it is more flexible and easier to bend than the other types of conduit.

- Liquid-tight flexible metal conduit is coated with plastic for a watertight seal, making it an ideal conduit type for outdoor applications such as powering an air conditioner.

- Rigid PVC conduit is a popular conduit type because of its cost and, with watertight fittings, its ability to be used above and underground. Although it can be bent, it is more difficult than with metal conduits and is better used for straight runs.

- Electrical non-metallic tubing is more flexible than PVC and installed with glued fittings and can be installed in tradition wood-frame installations as well as in concrete block or concrete-poured surfaces.

How to Choose Electrical Conduits for Your Application?

What conduit you choose will depend on a variety of circumstances. The first consideration is safety. If you are working outdoors or anywhere where water infiltration is a concern, you need to make sure that you have a long-lived conduit type that is also impervious to water penetration. Rigid metal and PVC are often preferred for these applications.

For everyday residential applications, the biggest considerations are cost and, if the conduit will be exposed, appearance. Rigid metal is the most expensive and is not required for conduit within framing, therefore, Intermediate metal conduit or Electrical metal tubing conduit are the preferred materials.

If you’re looking for flexibility and need to make multiple, sharp bends, flexible metal conduit offers a greater ease in bending the conduit to accommodate the dimensions of the installation.

As with everything, cost is one of the biggest factors; choosing the conduit that is the least expensive but most reliable for your installation will influence which conduit you choose.

Conduit: An electrician's friend

Whether you’re working in a residential or commercial setting, conduit can greatly ease the installation process as well as ensure that your wiring is code compliant, safe and effective. If you’re looking for a reliable name in conduit, LESSO conduit offers a variety of conduit for power supply and telecommunication installations. Our conduit is PVC or galvanized steel with appropriate fittings.

This conduit will allow you to tackle a variety of jobs, whether it involves HVAC, lighting or mechanical power supply. These materials are all extensively tested to ensure the highest performance ratings. We hope that you have a better understanding of the different types of conduits and how they can help your next electrical project; we look forward to helping you make your next installation an electrifying success!

Recommend Reading

Why Should You Use Conduit for Electrical Wiring?

When we talk about conduits, we are talking about pipes that are used to conduit electrical wiring through buildings. These conduits can be installed indoors

What is the Difference between Conduit and Trunking?

There is more than one option to store and keep cables organized during an installation. The containment systems you will select will be influenced by