The application of PE piping continues to expand as quality pipes are needed for water systems, gas distribution, submerged marines, and systems. As the demand for piping products rises, so does the need for simple PE pipes joining methods.

The companies that manufacture the PE pipes have made the system comprehensive to ensure compatibility with various fittings and components. Before you take a look at the PE pipe fittings catalogue, you need to learn about PE pipes fittings. Learning about the PE pipe fititngs will give you the knowledge you need for your next application. The article discussed in-depth PE pipes and PE pipe fitting and how to go about it.

What is PE Pipe Fittings?

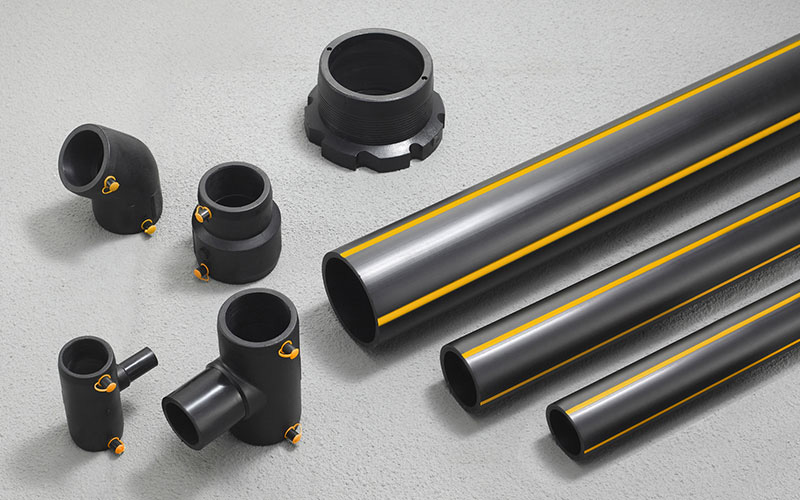

A fitting or adapter is used in pipe systems to connect straight sections of pipe or tube, adapt to different sizes or shapes, and for other purposes such as regulating (or measuring) fluid flow.

PE pipe fitting stands for Poly Ethylene pipe fitting. PE pipes can be connected to pipe in other materials by a range of mechanical fittings available from the relevant manufacturers. These can either be transition couplets to connect the pipes together directly or flange connections.

How to connect the PE pipes?

Unlike the PVC and the ABS pipes, the PE cannot be put together using glue or solvents. The method used to join the pipe need to either be heat welded or mechanical.

1. What Methods can be used to assemble a PE Pipe Network?

Electrofusion

Electrofusion fitting, also known as EF, is one of the simplest methods used in joining the PE pipe. The use of EF uses copper coils and winds it through the inner part of the fitting. Then the pipes get pushed into either side of the fitting, and then an electric current is passed through the coil. The heat from the current melts heat the copper coil, resulting in both the fitting and the pipe fusing pipes.

After the heat cycle is terminated, the pipes are left to cool and the two pipes from a sound joint. However, the electrofusion needs to be done right to be effective. There should also be satisfactory contact during the joining and cooling process.

Butt welding

The use of butt welding is another way you can use it to join the PE fittings. The process uses a specialized hydraulic clamping machine to cut the ends of the two pipes. When the pipes are trimmed are properly trimmed, the hot plate is placed onto both ends, and after heating, the plates are removed, and two ends are pushed together, causing them to melt. As a result of this joining method, a raised beam is formed. This can be an issue in the case where a smooth internal bore is needed. Though it is possible to remove the bead, it could result in other complications with the connection.

If you want to get the best joint, you need to make sure that the part being joined together is clean. If the surfaces are dirty, this could increase the possibility of contamination. Ensure that you use correct welding temperatures, pressure when joining and give the pipe ample time to fuse. If you do not want to deal with the bead, you can search for experts to properly remove it.

Compression Jointing

Another method that can be used to hold the PE pipe together is the compression couplings. This is a method that incorporates the pope firm and then pushes it through the O-Ring. After the procedure compression ring is then turned, and it is used to tighten the grip. The best material for making the fitting is the EPMD O-Ring.

The compression method is simple and does not need a professional to do it.

Hot melting

The connection of pe pipes and fittings could adopt hot-melt connection (hot-melt butt, hot-melt socket connection, hot-me lt saddle connection). Pipes with a nominal outer diameter greater than or equal to 63mm should not be connected by manual hot-melt sockets, pipes with a wall thickness of less than 6mm should not be connected by hot-melt butt joints, and polyethylene pipes and fittings should not be connected and bonded by thread.

2. Can different grades of PE be connected to each other?

It is possible to fuse different grades of PE pipes using any of the methods discussed above. However, to achieve the best outcome, the procedure needs to be carried out under controlled conditions. You also need to be careful not to collapse the thinner pipes during the fusion period. In case you are in doubt, it is best to consult the pipe and fitting supplier. Note that fusing different grades of PE could lead to the reduction of the maximum operating pressure.

3. How can PE pipe be connected to other pipe materials?

The PE pipes can be connected to other materials using various mechanical fittings that can be found from relevant manufacturers. Depending on the types of pipes you will be using, you might have to connect the pipes directly through the flange option. For the pipe to be connected, the outer body needs to be compatible with the pipe being joined.

You might also need to have an elastomeric sealing ring. The ring is essential as it helps keep the pipe tight, and an internal pipe stiffener can be used to offer long-term integrity. You need to ensure you have specified the size of the pope when ordering the fittings.

PE Pipe Joining Procedure

If you are planning on joining PE pipes, you need to let professionals handle the procedure. In case you are handling the PE pipe joining procedures then here is the procedure to use:

- Step 1: Have a flat surface to place your pipe. Leave a cutting allowance of 20mm.

- Step 2: Choose the right slip fixture for clamping. The fixture you use will depend on the pips you are using.

- Step 3: Center the end faces of the pipes you will be welding. It is essential to ensure that the offsetting does not exceed 10% to avoid poor results.

- Step 4: The next step is heating the two pipes the temperature used is between 2100-2300 depending on the season. Each end melting length is preferred 1-2mm.

- Step 5: Remove the hot plate and meet the two faces. Ensure you adhere to the required pressure. The switch should not take a long time.

- Step 6: Allow the fused pipes to cool but ensure that you maintain the docking pressure.

- Hot melting is the process of heating the two PE pipes using a hot melt machine.

- Electric melting is the process of equipped the electric heating wires and connecting them to the external column.

- Welding connection is the process of connecting the PE pipes using a welding machine.

Conclusion

It does not matter the project you have or the PE connection you will use. As long as you do not have quality PE pipes, then your project is bound to fail. In case you are looking for quality PE pipes, consider investing in a reliable company like the LESSO pipe supply company. The company has been in business for a long time and can offer the best service to its clients. They also have a variety of pipes to use in your project.