Table of Contents

Within the plumbing industry, it is important to understand there are different pipes to use. Whether the pipes are used for residential or commercial applications, understanding pipe sizes, the materials they are made with, and their compatibility will be essential to ensure proper installation, repairs, and maintenance.

The correct piping can ensure efficient water flow and the prevention of leaks. It also helps in selecting the right materials for specific plumbing jobs. When it comes to choosing between PP and PPR pipes (polypropylene vs polyethylene) it pays to understand what they are and the advantages of each.

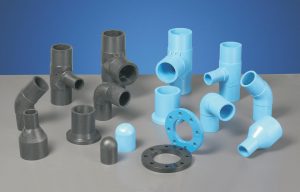

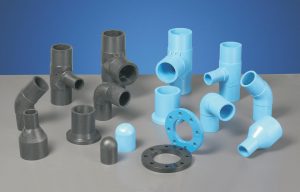

When it comes to choosing a reliable and reputable brand for your pipe needs, LESSO pipe is an excellent choice. With a solid reputation in the industry, Lesso offers a wide range of high-quality pipes, including PP and PPR options, that meet rigorous standards for durability, performance, and safety. Their pipes are known for their excellent resistance to corrosion, high temperature, and pressure.

Whether you need pipes for hot water distribution, cold water systems, or other plumbing applications, Lesso provides reliable solutions. By selecting Lesso, you can have confidence in the quality and longevity of your plumbing installations, backed by a trusted brand known for its commitment to excellence. Contact the professionals at Lesso for your residential and commercial piping needs!

What is PPR?

What does PPR stand for? PPR stands for polypropylene random pipes. They are a type of plastic piping system widely used in plumbing applications. Made from a special random copolymer of polypropylene, a PPR pipe offers excellent resistance to high temperatures and pressure, making them ideal for both hot and cold water distribution. They are known for their durability, longevity, and ease of installation through heat fusion welding, ensuring leak-free joints.

PPR (polypropylene random) pipes are made from a special random copolymer of polypropylene. They offer excellent resistance to high temperatures, pressure, and chemicals, making them ideal for hot and cold water distribution systems. With low thermal conductivity and easy installation through heat fusion welding, PPR pipes ensure longevity and reliability in plumbing applications.

A PPR pipe offers several advantages in plumbing applications. They are resistant to high temperatures, pressure, and chemicals, ensuring durability and reliability. They have low thermal conductivity, easy installation through heat fusion welding, and are suitable for hot and cold water distribution systems, making them ideal for residential, commercial, and industrial plumbing projects.

What is PP?

PP pipes, also known as polypropylene pipes, are a type of plastic piping system commonly used in plumbing applications. They are made from polypropylene, a thermoplastic material known for its durability and resistance to chemical corrosion. PP pipes are typically used for cold water systems, drainage, sewage, and irrigation.

Due to PP pipes being composed of polypropylene, they are a versatile thermoplastic material known for its durability and resistance to chemical corrosion. PP pipes have excellent chemical resistance, making them resistant to corrosion from various substances.

They are lightweight, making handling and installation easier. With good impact resistance and long service life, PP pipes are commonly used in applications such as cold water systems, drainage, sewage, irrigation, and industrial processes.

Polypropylene vs Polyethylene Pipes

The basic differences between PP (polypropylene) and PPR (polypropylene random) pipes lie in their material composition, pressure and temperature ratings, flexibility, and applications.

While PP pipes are typically used for cold water systems, PPR pipes, made from a special random copolymer, are suitable for both hot and cold water applications with higher pressure and temperature resistance.

PP (polypropylene) pipes are lightweight, flexible, and suitable for cold water systems but have limited temperature and pressure resistance. PPR (polypropylene random) pipes, with their special copolymer composition, offer higher temperature and pressure resistance, making them ideal for hot and cold water applications but are less flexible than PP pipes.

The differences between PPR (polypropylene random) and PP (polypropylene) pipes significantly impact their applications and suitability in plumbing systems. PPR pipes, with their higher temperature and pressure resistance, are well-suited for both hot and cold water distribution systems, making them ideal for residential and commercial plumbing.

On the other hand, PP pipes, with their flexibility and corrosion resistance, are commonly used for cold water systems, drainage, sewage, and irrigation. Understanding these differences helps in selecting the right pipe for specific plumbing needs, ensuring efficient and durable installations.

Applications of PP and PPR Pipes

PP (polypropylene) pipes find common applications in various areas of the plumbing industry. They are often used in cold water systems for residential, commercial, and industrial buildings. PP pipes are suitable for transporting potable water, drainage, wastewater, and irrigation.

Their corrosion resistance makes them ideal for outdoor applications as well. Additionally, PP pipes are employed in plumbing systems for swimming pools, aquariums, and water treatment facilities due to their durability and compatibility with different water types.

Real-World Use of PP Pipes:

Example 1: In a residential setting, PPR pipes were installed for a hot water distribution system. Their high-temperature resistance ensured efficient delivery of hot water to various faucets and showers, providing comfort and convenience to homeowners.

Example 2: In an agricultural irrigation project, PP pipes were used to transport water from a reservoir to crop fields. The lightweight and corrosion-resistant nature of PP pipes made them ideal for long-distance water supply, ensuring efficient irrigation and minimizing maintenance needs in challenging outdoor conditions.

Final Thoughts

In conclusion, understanding the differences between PP (polypropylene) and PPR (polypropylene random) pipes is crucial for plumbing professionals. It enables them to make informed decisions and select the most suitable pipe for specific plumbing applications.

The temperature and pressure resistance disparities between the two types of pipes determine their applicability in hot or cold water systems, affecting the overall performance and longevity of the plumbing installation.

Additionally, considering the flexibility of PP pipes and the rigidity of PPR pipes helps professionals determine the most appropriate choice for different pipe runs and configurations. By understanding these distinctions, plumbing professionals can ensure efficient water flow, prevent leaks, and provide durable and reliable plumbing systems for their clients.

Ultimately, this knowledge empowers professionals to deliver high-quality work, meet industry standards, and provide optimal solutions tailored to the specific needs of each plumbing project.

Applications of PE Pipe

Table of Contents The requirement for high-quality pipes in water and gas distribution, submerged marines, and other systems means that PE piping’s use will only

What are the Main Uses of PPR Pipe?

PPR Pipe has been growing in popularity over the last couple of years, and rightly so. Its durability, ecological, and economic benefits make PPR pipes