General Regulations

- Check wether the appearance quality and size of the pipe and fittings comply with the requirements of design and construction before construction. Forbidden to use the pipe carried obvious scratch.

- Review the S series of LESSO pipe before construction, the mark on the pipe should face the outer side and place in the apparent location.

- All of the machines used for solvent weld connection should be supplied by the manufacture, or the special welding machines have been verified by the authority parties.

- Use special pipe cutter to cut the pipe, the fraction surface should be vertical with the center line of the pipe.

- Seal up all of the open area immediately when discontinue the construction.

- Pay attention to the low temperature brittleness of PP-R pipe when construct in winter.

- The pipe system can be sealed and used after it passed the water pressure test and final acceptance.

Cross of the Pipe

- The anti-leakage measurements should be well prepared before cross the pipe. The crossing parts should be constructed with the clamps in the pipe system, take anti-leakage measurements, and fix the pipe well.

- Pre-bury the steel waterproof sleeve when the pipe crosses the concrete wall in the basement.

- Pre-bury the PVC-U sleeve when the pipe crosses brick wall or steel reinforced concrete wall.

- Well prepare the anti-leakage measurements when the pipe crosses the roof surface for bearing persons or non-bearing persons.

- Lay the pipe under the concrete floor and cross the floor when introduce the pipe in the house from outside.

- When the water inlet, outlet and drain to empty pipe or other pipes cross the steel reinforced concrete pool (or water tank), the crossing pipe sections should be used coated steel-plastic composite pipe or stainless steel pipe with function of corrosion resistance from inner and outer side.

- Use corner type when introduce the pipe into the house, the length of the corner sections should be determined by the descendant length of the building, generally not less than 700mm.

- When the pipe crosses multilayer of strips basic, then there should be gaps with height no less than 120-150mm on the pipe top.

Installation of the Holder and Hanger

- Set clamps, holders or hangers according to different diameters and requirements in the installation. The location of the clamps, holders or hangers should be precise, and the setting should be smooth. Though the clamp set close to the pipe, it should not damagethe surface of the pipe.

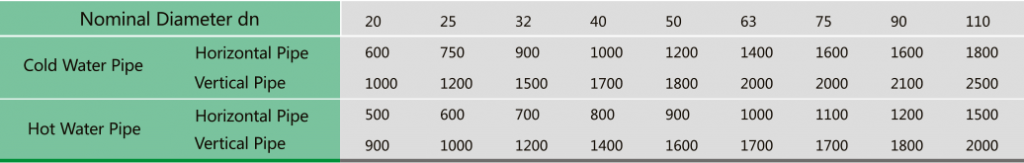

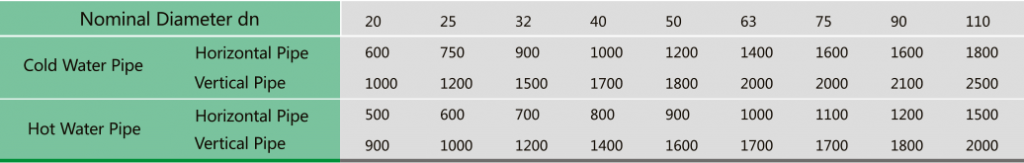

- In the vertical and horizontal pipe systems, the distance between the holders, hangers or clamps should comply with the requirements in the chart below, (mm)

- When the pipe connects with metal accessories, the clamps, holders or hangers should be set on the metal accessories.

- When use metal clamps, metal holders or metal hangers, the inner side of the hoops should be cylinder. And there should be gasket such as rubber gasket between the hoops and the pipe. The body of the fixed holders and hangers should bear enough stiffness. They should not deformed.

- Set reliable fixing measurements on the parts of tee, elbow, end of the water distribution point, valve, and the parts where the pipe crosses wall (or floor). The bending leg for compensate the flexibility of the pipe should not be fixed.

Note: When the cold water pipe and hot water pipe share the same holders and hangers, the distance between the holders and hangers should be determined according to the requirements of hot water pipe. As regarding to the straight buried pipe, the distance between the clamps of cold water and hot water pipe can use 1.00〜1.50m.

Anti-frozen, Heat Isolation and Heat Preservation of the Pipe

- The pipe introduced into the house should be laid under the local frozen line. The thickness of the back fill earth above the pipe top should not less than 300mm.

- The PP-R pipe should not be surface installed in outdoor. Or take effective shading measurements when unavoidable.

- Take anti-frozen measurements when install the pipe in the area where may froze.

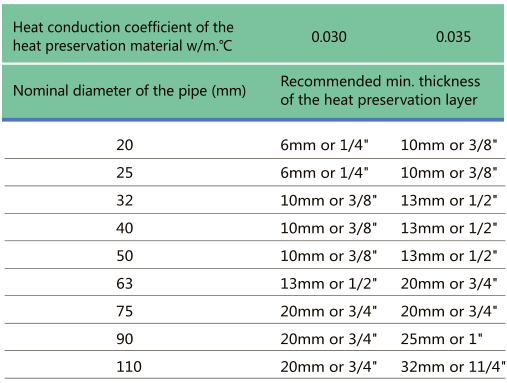

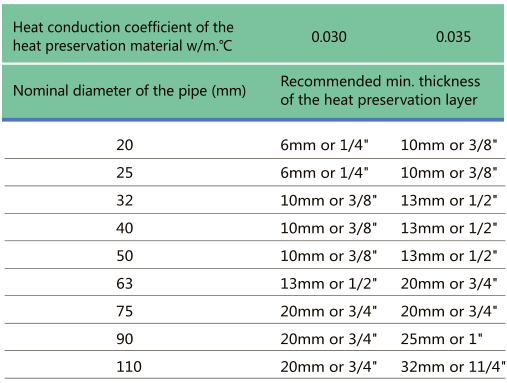

- As regarding to the surface installation hot water pipe, the min. thickness of hear preservation layer has been showed in the chart below.

- Set reliable fixing measurements on the parts of tee, elbow, end of the water distribution point, valve, and the parts where the pipe crosses wall (or floor). The bending leg for compensate the flexibility of the pipe should not be fixed.

Safety Construction

- Check the electric power and the voltage when using the solvent weld or electro fusion machines. Comply with the safety operation regulations of the electric tools. Maintain the cleaning of the tools and pay attention to prevent damp.

- There should be no flame in the construction site. Forbidden to store inflammable fluids in the construction site, and forbidden to bend the PP-R pipe by using flame.

- Check if there’s any objects block the pipe before connection. Seal up the pipe end when stop construction temporarily.

- After seal the straight buried pipe, stick related marks on the wall or the ground surface where buried the pipe. Forbidden to knock or peg metal nail or other sharp objects above the pipe.

You May Also Like

Post Views: 5,153