Table of Contents

Electrical conduits are usually tubular in shape and play a vital role in the safety of our modern world. In residential and commercial structures, you’ll typically see them in crawl spaces, basements, exterior walls and outdoors.

Numerous commercial applications use them, including bridges, subway lines, railroads, sea ports and information data centers. Their purpose is to protect the electrical wires that they encase. There are at least eight basic types of electrical conduits, ranging from rigid metal to fiberglass. Only some of them perform well as underground electrical conduits.

Choosing the right material directly impacts the protection a conduit can deliver. Use this guide to learn why choosing the right conduit for electrical wire underground is important and how to select the right one for your project.

Why Choosing the Correct Electrical Conduit is Important

Underground electrical conduits protect wiring and cables from several elements, including moisture, short-circuits, rust, external impact, electric shock and fire. Exposure to these elements can lead to moisture and water ingress, thermal expansion issues, conductor overcrowding and so much more. All of these damages impact the performance of the equipment the conduits connect to.

Not choosing the right electrical conduit presents a variety of safety concerns. Inadequate protection leaves underground electrical wiring vulnerable to physical damage, which increases the risk of electrical shocks. Incorrect conduit materials also enhance the risk of fire due to their inability to provide adequate heat resistance.

As the wires overheat, they can easily cause fire damage. Additionally, selecting a conduit that doesn’t provide sufficient protection against moisture raises the likelihood of short circuits and equipment failure. This exposure to moisture accelerates the risk of corrosion and degradation over time.

When selecting the wrong conduit, safety and functionality issues aren’t the only concerns you have to deal with. Using the wrong conduit can cause compliance issues with local codes and standards. All cities and towns have their own codes. Not complying with these codes can result in fines and penalties, as well as having to demolish a structure if you refuse to make the necessary improvements.

How Deep to Bury Electrical Conduit Underground?

Safety should always be your top priority when burying an underground electrical conduit. If you don’t bury it deep enough, you risk the wires coming into contact with humans, animals and weather elements. This not only puts the conduit and wiring in harm’s way but can also lead to serious injury or even death.

Choosing the right material prevents the conduit and wiring from collapsing and causing other types of damage. Some projects require protecting the conduit from temperature fluctuations by using expansion joints or other types of flexible connections. These connectors give the conduit plenty of space to move as it expands and contracts when the temperature changes.

A project’s location, setting and wiring method directly impact which electrical conduit will work best and how deep to bury it. Generally, the burial depth varies from four to 24 inches below the ground. The National Electrical Code (NEC) makes it easy to understand and implement new regulations for safe electrical wiring. The NEC’s goal is to provide a methodical approach to preventing harm to people and property from electrical sources.

Both voltage and material impact depth guidelines for electrical conduits. Low-voltage PVC conduits (under 600V) typically require a minimum depth of 18 inches in residential structures. In non-residential structures, PVC conduits need a burial depth of at least 24 inches. For rigid metal, the underground depth is only six inches for low-voltage wiring in residential settings. In non-residential settings, the minimum depth requirement is 18 inches.

Medium-voltage conduits (600V to 35kV) usually require a burial depth of 18 to 24 inches, but this varies depending on the material. Some high-voltage conduits require even greater depth. Other factors that influence how deep to bury an electrical conduit are soil type, local weather patterns, exposure to chemicals in the ground, the size of the wires and any future plans to upgrade or expand the electrical system.

Underground Conduit Options Available

Projects that want to use traditional metal conduits have two basic types to choose from: rigid metal conduit (RMC) and electrical metallic tubing (EMT). However, due to its thin walls, fragility and necessity for specialized water-resistant connections, professionals don’t recommend using EMT for subterranean conduits.

RMC, on the other hand, does perform well as an underground electrical conduit, especially in areas that endure a lot of traffic, such as underneath driveways.

In the past, most construction projects used traditional steel or aluminum metal conduits because of their durability. However, thanks to advancements in technology, we now have cheaper, lighter alternatives. One such option is PVC. Contractors readily prefer to use PVC conduits for underground purposes.

These conduits perform exceptionally well in wet locations and boast several benefits for underground use. They are watertight in both freshwater and saltwater settings, as well as fire-resistant. PVC conduits also work well in areas exposed to UV rays.

Over the past few years, engineers and builders have encountered supply chain problems with PVC conduits. These problems have increased the cost of PVC and resulted in long waiting periods for shipping fulfillment.

In response, many engineers and builders began using fiberglass conduits. When evaluating underground conduit types in regards to their cost, fiberglass conduits are the most affordable option.

The light weight of the fiberglass makes them easy and cheap to install. Fiberglass conduits perform incredibly well underground because of their resistance to extreme temperatures, high humidity and corrosion.

The conduits are also non-toxic, making them environmentally friendly. In addition, using fiberglass conduits means that lengthy cable pulls are safe from burn-through thanks to the material’s low coefficient of friction.

Which Conduit Is Best for Your Below-Ground Application?

Selecting the right type of conduit for electrical wire underground affects your safety and the performance of the electrical system. To ensure you choose the right type, there are several factors you need to carefully consider. For starters, the

soil type, level of moisture in the ground and exposure to corrosive elements all impact which type of underground conduit to use. PVC conduits are resistant to moisture, while rigid metal conduits usually work best in above-the-ground projects. You also need a qualified technician to determine the voltage and current levels that the conduit will carry. Higher-voltage applications sometimes require a specialized conduit.

Keep in mind that some conduit types work better underground than others, particularly fiberglass and PVC conduits. However, there are other options to choose from. Some contractors recommend using HDPE pipes, geothermal HDPEs, split PVC conduits or CIC/cable conduits to protect electrical wires in the ground.

Choosing the right underground conduit also requires verifying compliance with local building codes and regulations. The contractor performing the installation can update you on the latest codes and guarantee you stay in compliance.

Always consider any potential future maintenance, repairs or expansions that the conduits will need. Installing conduits with easy access points can improve maintenance requirements, especially for projects that require regular updates.

Consider the upfront cost of materials and installation versus the long-term durability and maintenance requirements of a conduit. The most affordable conduits are those made from fiberglass or PVC. Both types offer enhanced durability. You’ll also find it helpful to test how simple it is to pull wires through the conduit. Conduits with smooth inner surfaces usually work best, while those with curved or ribbed edges make it difficult to pull wires through.

Lastly, it’s important to assess whether the conduit is likely to come into contact with chemicals or corrosive substances. Fiberglass conduits contain an epoxy resin coating that makes them highly resistant to damaging chemicals.

How LESSO Can Help

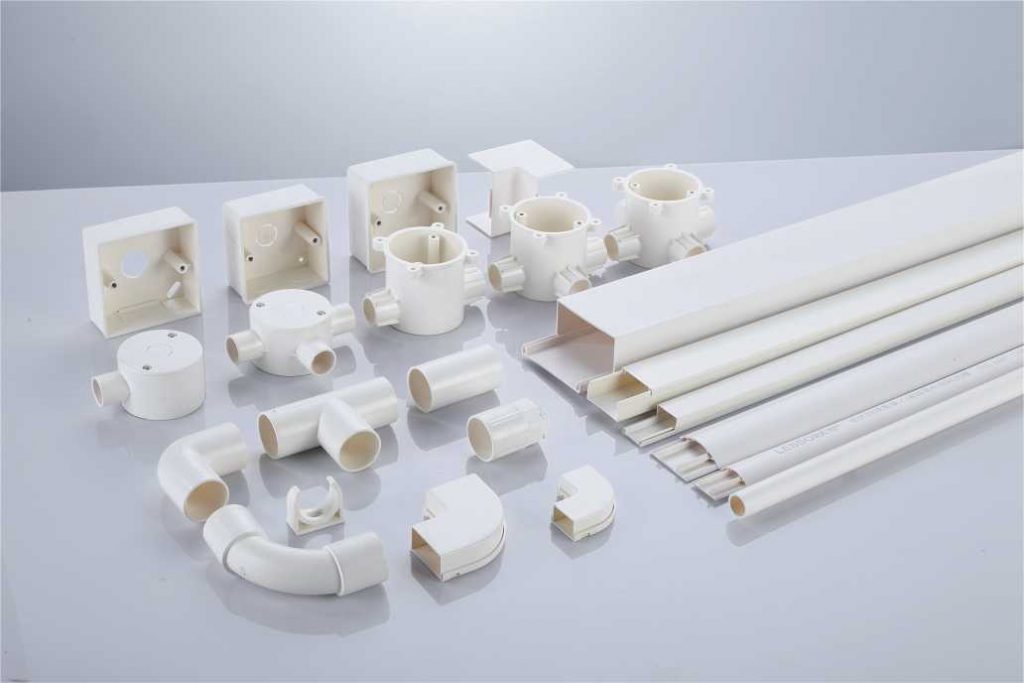

LESSO is an industry leader in the electrical conduit sector. The company works with contractors of all types, including residential and commercial builders. All of the company’s pipes undergo extensive testing to guarantee optimal performance. Some of the various PVC conduit products that LESSO specializes in working with are:

- PVC round-type wiring duct

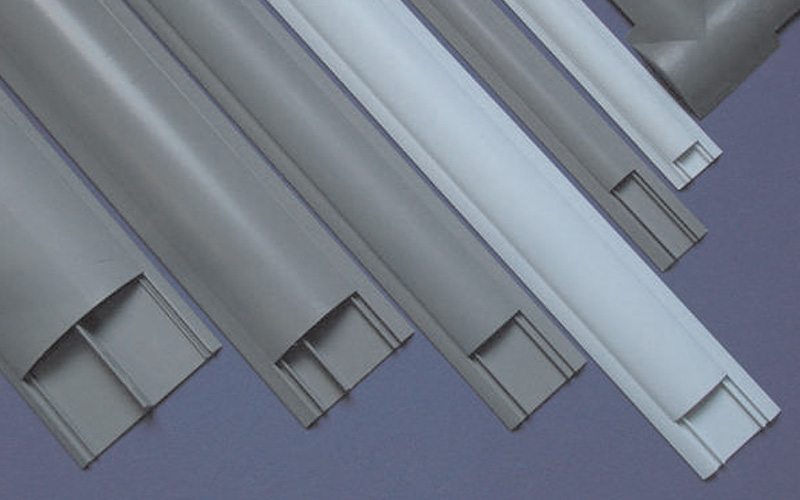

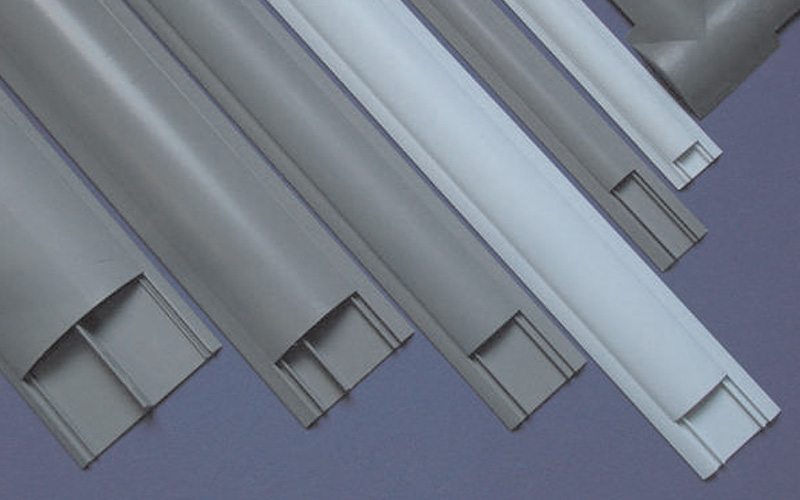

- PVC multifunctional trunking and fittings

- PVC conduit and fittings

- Galvanized steel conduit

- PVC air-conditioning duct

LESSO helps homeowners and commercial builders with a wide range of applications that require the use of electrical conduits, including water supply, drainage and sewage, power supply and telecommunications, floor heating and fire protection projects.

We provide comprehensive services, beginning with project planning all the way through product installation and after-sale support. We also offer several resources to help you make a well-informed decision when choosing the right underground conduit, including user manuals, installation guides and blog posts.

Conclusion

Installing the right conduit is crucial to any electrical project. It not only ensures the conduit is appropriate for the project’s environmental setting and voltage requirements, but it also guarantees safety and compliance with local codes. The best way to make an informed decision is to consult with an experienced professional who can assess the specifics of your project, including any future accessibility requirements.

FAQs about Underground Conduit

Follow local codes and manufacturer recommendations to provide adequate ventilation for enclosed conduits.

Always turn off the power supply before working on electrical conduits, use proper personal protective equipment (PPE), and consult a licensed electrician for complex tasks.

Refer to the National Electrical Code (NEC), the National Fire Protection Association (NFPA), and manufacturer specifications for detailed guidance.

Recommend Reading

How Deep Should An Electrical Conduit Be Buried

Table of Contents Electrical conduits are the lifelines of modern infrastructure, seamlessly transporting power through a labyrinth of hidden pathways. Ensuring these vital channels are

What’s the Difference Between PVC Pipe and PVC Conduit

Table of Contents PVC or Polyvinyl Chloride pipes use vinyl and plastic materials. We use these pipes in plumbing systems. If you do not want