Table of Contents

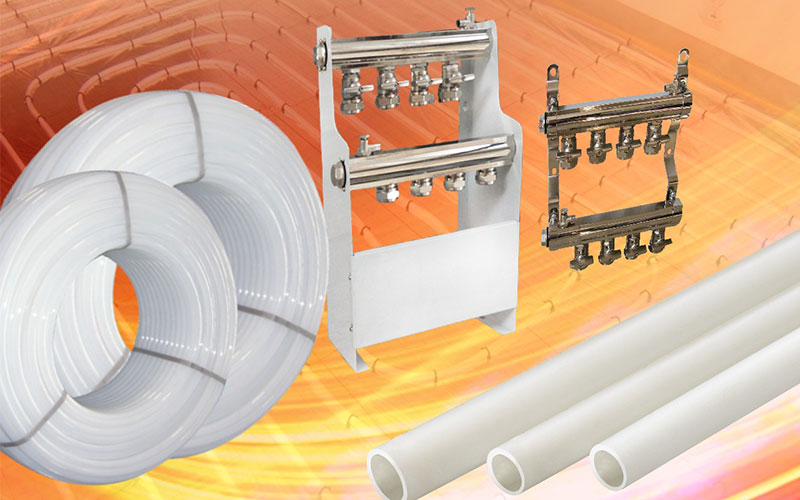

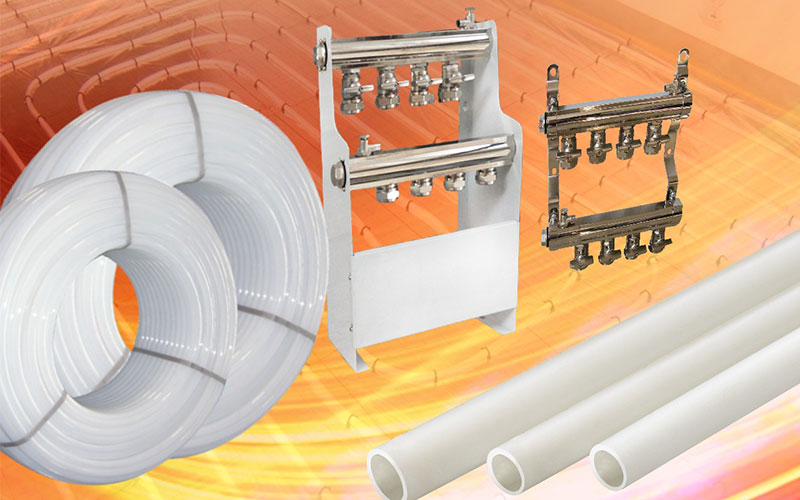

Designing an underfloor heating system requires you to select the right pipes and identify how hot water will be distributed into the building. Underfloor heating systems rely on high-quality pipes to heat rooms of all sizes. Hot water is sent through these pipes by a boiler or heat pump.

The entire system is placed under the flooring material. Because of how hot the water can get, it’s crucial that you choose the right pipes for the task at hand. Some pipe materials don’t accommodate high water temperatures. The following guide offers an in-depth comparison between PE-RT and PEX pipes for underfloor heating.

Overview of PE-RT Pipes

PE-RT refers to polyethylene of raised temperature resistance. These pipes are built with durable polyethylene materials that are capable of resisting high water temperatures. They also deliver superior hydrostatic strength, which is necessary in high-temperature environments. Because of the many benefits associated with this piping material, it’s been used in residential and industrial applications for decades.

To understand what is PE-RT pipe, consider the fact that these pipes have enough flexibility to bend at angles necessary for underfloor heating. They can be placed under nearly any type of flooring material. This material is routinely used in power plants and residential homes.

A PE-RT pipe offers many advantages that can’t be had with a PEX pipe, which include the following:

- High level of flexibility

- Ample heat resistance

- Suitability for underfloor heating applications

- Lightweight material

- Eco-friendly

- Great flow capacity

Advantages of PE-RT in Underfloor Heating

There are many benefits of using a PERT tube for underfloor heating, the primary of which is that it offers high heat resistance. Because of the high heat resistance, these pipes are suitable for underfloor heating applications. You’ll also discover that the material doesn’t need to be cross-linked in order to provide high durability and strength. PE-RT pipes should last for many years.

When you’re considering using PE-RT pipes, keep in mind that they are the only polyethylene solution you can use. Traditional polyethylene doesn’t hold up well in applications with high temperatures. Some additional benefits associated with this piping material include the following:

- High durability and toughness

- An Eco-friendly and recyclable material

- Freeze-break resistance

- Lightweight

- Long-term solution

- Ample resistance to scale buildup

- Noise resistance

- Flexibility

Comparison: PEX vs. PE-RT

The two types of piping that are regularly used for underfloor heating include PEX and PE-RT. As mentioned previously, PE-RT pipes are made from a type of polyethylene that’s designed to have high heat resistance. This characteristic ensures that the material can be used for any underfloor heating application.

If you’re wondering “What does PEX stand for?”, the answer is that it applies to cross-linked polyethylene, which is a significantly more rigid form of plastic that can be used to deliver water to commercial and residential buildings. Even though the material is rigid, it has high flexibility, which allows it to be easily installed around corners or tight spaces.

PEX and PE-RT pipes are resistant to chemicals and corrosion. They are also lightweight piping materials that shouldn’t create problems during the installation process. While PE-RT is considered to be more affordable than PEX, they are both low-cost materials in comparison to other piping solutions on the market. However, PEX can’t resist heat as well as PE-RT.

Installation and Maintenance Requirements

The installation process isn’t too difficult for either PE-RT or PEX pipes. Since PEX is known for its considerable flexibility, it’s easy to install the material in spaces that don’t have much room for pipes. If you find that you need to install pipes around tight corners, this is possible with PEX. PE-RT pipes are also flexible but can be challenging to install around corners and tight spaces. These pipes have a higher stiffness than PEX ones.

When considering maintenance for PE-RT pipes, they can be effectively repaired with a hot-melt connection. Keep in mind that the pressure resistance won’t worsen even after a hot-melt connection is made. As for PEX pipes, the only way to repair them is by using external pipe clamps.

Cost-benefit Analysis

When you’re buying PE-RT pipes, you can expect to pay anywhere from $0.20-$1.00 per linear foot. In comparison, PEX pipes cost upwards of $0.40-$2.50 per linear foot. Even though PEX pipes can cost more than PE-RT ones, they typically cost the same.

The main issue with PEX is that it doesn’t have a high heat resistance, which makes it prone to cracking and other issues when used for underfloor heating. You won’t need to worry about these issues with PE-RT pipes.

Because of these advantages, PE-RT pipes are much more cost-effective in comparison to PEX ones. They’re also better as a long-term investment. Since PE-RT pipes hold up well to high temperatures, they’ll last longer when used for this application.

Environmental and Sustainability Impact

When you’re comparing PE-RT vs PEX pipes, neither material is bad for the environment. However, the polyethylene material that’s used in the making of PE-RT pipes is recyclable and sustainable. From the initial manufacturing process to the eventual usage, PE-RT pipes hold up well. Excess waste isn’t created during the manufacturing process.

If you’re considering PEX pipes, keep in mind that manufacturing these pipes produces more waste. They also become brittle at very high temperatures, which can cause them to crack. In this scenario, the materials from the pipes can pollute the ground.

Conclusion: Choosing PE-RT for Underfloor Heating

There are many reasons why it’s a good idea to choose PE-RT pipes for your next underfloor heating project. From high flexibility and ample heat resistant to low costs and few maintenance requirements, you should use PE-RT piping for your next underfloor heating project.

While PEX piping offers some advantages, PE-RT is the ideal solution for underfloor heating because of its environmental benefits and superior characteristics. Contact LESSO today to find high-quality pipes at an affordable price.

FAQs about Underfloor Heating Pipe

Yes, PERT is compatible with most underfloor heating setups due to its versatility.

Service life is up to 50 years for pipe. The central heating system has nominal service life of up to 30 years, which depends on varied application condition(such as temperature, pressure, etc)

No, PERT pipes are easier to install due to their flexibility and require less maintenance.

Recommend Reading

Ultimate Guide: Designing the Perfect Underfloor Heating Pipe Layout

Table of Contents Introduction to Underfloor Heating and Piping Layout Planning is crucial. In fact, it’s the most important thing of all when it comes

Ultimate Guide to Floor Heating Pipe

There are various heating systems used in homes, and floor heating is one of the best ways to heat your home. Floor heating can emit